What is the industrial computer?

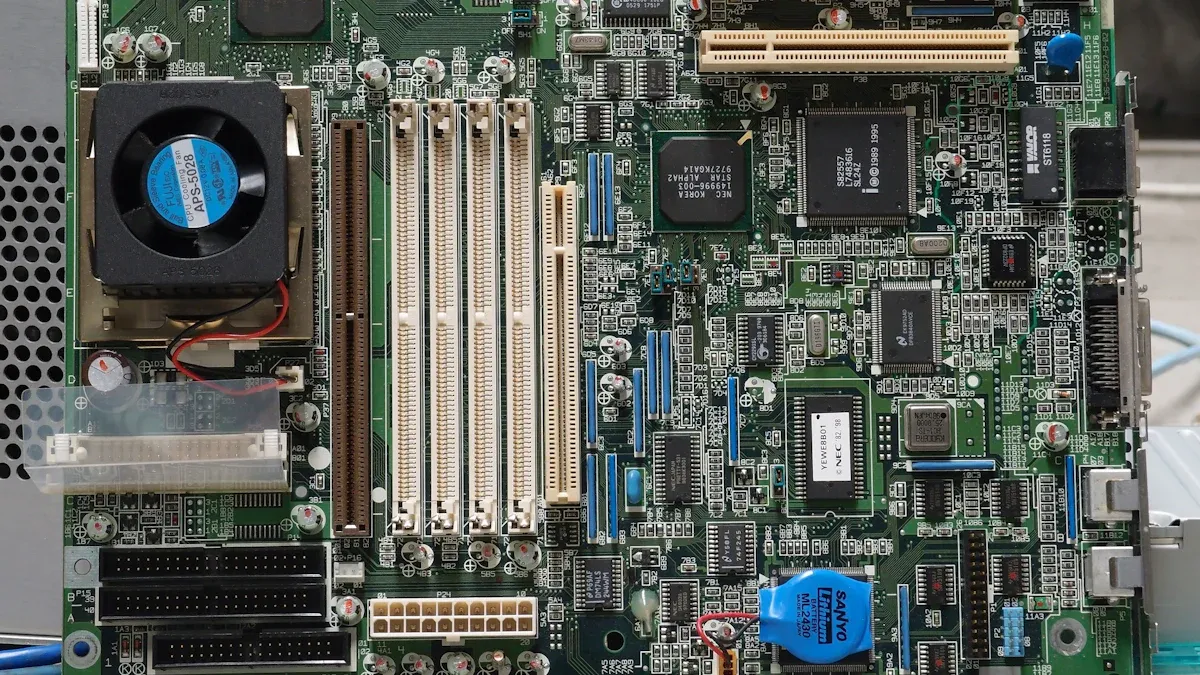

An industrial computer is a specialized computing device designed to operate in demanding environments. Unlike standard PCs, it withstands extreme conditions like high temperatures, dust, and vibrations. You’ll find these computers essential in modern industries for tasks such as managing motion control systems, automating production lines, and monitoring machinery. They also streamline operations by tracking inventory, running quality control tests, and ensuring smooth production processes. Built for durability and longevity, industrial computers meet specific industry needs through hardware and software customization, making them a cornerstone of industrial automation and efficiency.

Key Takeaways

Industrial computers are made to handle tough conditions like heat, dust, and shaking. They are important for hard-working places.

These computers can be changed to fit what industries need. This helps them work better and faster.

Buying industrial computers saves money over time because they last longer and need less fixing than regular PCs.

Industrial PCs keep working with little downtime, which is very important for jobs like making products or healthcare.

Their strong build and dependability make them a must-have for areas like energy, transportation, and defense.

Key Features of an Industrial Computer

Rugged Design

Resistance to extreme temperatures

Industrial computers excel in environments where standard PCs fail. You can rely on them to operate in extreme heat or cold without performance issues. These systems often use fanless, passive cooling designs to manage heat efficiently. This eliminates moving parts, reducing the risk of failure in harsh conditions. Whether in a freezing warehouse or a scorching factory floor, an industrial computer ensures uninterrupted operation.

Protection against dust, moisture, and vibrations

Industrial PCs are built to withstand challenging environments. Their rugged design includes protection against dust, moisture, and vibrations. Many models come with IP ratings, such as IP65, which means they are dust-tight and resistant to water ingress. This makes them ideal for industries like food manufacturing, where equipment may need regular washdowns. Additionally, their shock-resistant construction ensures they can handle high levels of vibration, up to 50G, without compromising performance.

High Performance and Customizability

Powerful processors and components

Industrial PCs are equipped with robust processors and components designed for demanding tasks. They maintain high performance even in environments with electromagnetic interference (EMI). This ensures reliable operation in settings with multiple devices, such as manufacturing plants or telecommunications hubs.

Tailored configurations for specific applications

You can customize industrial computing solutions to meet your unique needs. For example, industries like automotive or telecommunications benefit from custom industrial connectors. These connectors ensure seamless integration and optimal performance, tailored to specific applications. This adaptability makes industrial PCs a versatile choice for various sectors.

Longevity and Reliability

Extended lifespan compared to commercial PCs

Industrial computers are designed to last longer than commercial PCs. They feature higher Mean Time Between Failures (MTBF) and often come with extended warranties. This reduces the need for frequent replacements, saving you time and money.

Minimal downtime in critical operations

Reliability is crucial in industrial settings. Industrial PCs minimize downtime by offering consistent performance and durability. Their long lifecycle and reduced maintenance needs make them a cost-effective solution for critical operations.

Differences Between an Industrial Computer and a Commercial PC

Durability and Build Quality

Materials and construction suited for harsh environments

Industrial computers are built with industrial-grade materials that undergo rigorous testing for durability. These materials, such as reinforced steel or high-quality aluminum, ensure the computer can withstand extreme conditions. For example, an industrial computer can operate in temperatures ranging from -40°C to +85°C, making it suitable for environments where temperature control is not feasible. In contrast, commercial PCs use thinner aluminum or acrylic plastic, prioritizing cost-effectiveness and aesthetics over durability. This difference in construction ensures industrial PCs perform reliably in challenging environments, while commercial PCs are more prone to wear and tear.

Comparison with standard commercial PC designs

The design of an industrial PC focuses on functionality and resilience. Features like dust-resistant enclosures, vibration-proof components, and moisture protection make them ideal for harsh settings. On the other hand, commercial PCs prioritize user-friendly designs and sleek appearances. These computers are intended for indoor use, where environmental factors like dust or vibrations are minimal. As a result, industrial PCs offer a level of durability that commercial PCs cannot match.

Performance and Scalability

Industrial computers' ability to handle demanding tasks

Industrial PCs are equipped with high-end components, such as industrial-grade processors and robust input/output interfaces. These components allow them to handle demanding tasks like real-time data processing or controlling automated systems. In contrast, commercial PCs rely on consumer-grade components, which may struggle with such workloads. This makes industrial computers a better choice for industries requiring consistent and powerful performance.

Expandability for future needs

Industrial PCs are designed with scalability in mind. You can easily upgrade or customize them to meet future requirements, such as adding more memory or integrating new hardware. This adaptability ensures your investment remains relevant as technology evolves. Commercial PCs, however, often lack this level of expandability, limiting their usefulness over time.

Cost and Lifespan

Higher initial investment but better long-term value

While industrial computers require a higher upfront investment, they offer better long-term value. Their robust construction and extended lifespan reduce the need for frequent replacements. Over time, this saves you money compared to the recurring costs of replacing commercial PCs.

Reduced maintenance and replacement costs

Industrial PCs are designed for reliability, which minimizes maintenance needs. For example, they resist dust and moisture, reducing the likelihood of damage. A comparison of maintenance costs shows that industrial PCs have lower overall costs due to their durability and reduced downtime. In contrast, commercial PCs often require more frequent repairs, leading to higher maintenance expenses.

Tip: Investing in an industrial PC may seem costly at first, but its reliability and longevity make it a cost-effective solution for demanding environments.

Advantages of Industrial Computers

Operability in Extreme Conditions

Functionality in high/low temperatures

Industrial computers excel in environments where standard PCs fail. These rugged systems operate reliably in extreme heat or freezing cold. For example, they function seamlessly in temperatures ranging from -40°C to +85°C. This makes them ideal for industries like oil and gas, where equipment must endure harsh climates. Their fanless cooling systems also prevent overheating, ensuring consistent performance even in challenging conditions.

Resistance to environmental hazards

You can depend on industrial computers to resist environmental hazards like dust, moisture, and vibrations. These systems feature sealed enclosures with high IP ratings, such as IP65, which protect against water and dust ingress. They also withstand high shock and vibration levels, making them suitable for industries like transportation and manufacturing. Unlike standard PCs, these computers maintain functionality in environments filled with particulates or moisture.

Enhanced Reliability

Consistent performance in critical operations

Industrial computers deliver consistent performance in critical operations. Their robust design ensures uninterrupted functionality, even in demanding settings like assembly lines or power plants. For instance, rugged industrial computers are engineered to handle electromagnetic interference, ensuring smooth operation in environments with multiple devices. This reliability reduces the risk of operational delays.

Reduced risk of failure

You minimize the risk of failure by using industrial computers. Their durable components and extended lifespans make them less prone to breakdowns. These systems also feature high Mean Time Between Failures (MTBF), which means they last longer than commercial PCs. This reliability is crucial for industries where downtime can lead to significant losses.

Custom Solutions for Specific Needs

Adaptability to unique industrial requirements

Industrial computers adapt to meet your specific needs. For example, in the oil and gas industry, custom-built systems comply with safety standards and withstand extreme conditions. In pharmaceuticals, rugged computers ensure sterile operations while offering customizable data entry options. This flexibility makes them a valuable asset across various sectors.

Industry | Custom Solution Description |

|---|---|

Oil and Gas | |

Pharmaceuticals | Rugged computers that meet safety requirements for sterile operations and are customizable for data entry. |

Military | Computing systems that meet military standards for shock and temperature resistance, using cost-effective components. |

Integration with existing systems

Industrial computers integrate seamlessly with your existing systems. For instance, the KCO-3000-RPL model demonstrates easy installation and interoperability with current components. These systems also support legacy devices and applications, which is essential for factories that cannot frequently upgrade their infrastructure. This compatibility ensures continuous operations without extensive reconfiguration.

Industries and Applications of Industrial PCs

Manufacturing and Automation

Use in assembly lines and robotics

Industrial PCs play a vital role in the manufacturing industry by enhancing efficiency and precision. You can use them to manage motion control systems, which are essential for tasks like data logging, inspection, and analysis. These systems streamline production processes, ensuring assembly lines and robotics operate smoothly. For example, in the automotive sector, industrial PCs automate repetitive tasks, reducing errors and increasing productivity. Their robust design allows them to withstand the harsh conditions often found in factories, making them indispensable for industrial automation.

Monitoring and controlling production processes

Industrial PCs excel at monitoring and controlling production lines. They ensure machinery and tools function optimally, preventing costly downtime. You can rely on them to track inventory levels, guaranteeing raw materials are always available. Additionally, they run quality control tests on finished products, ensuring high standards are consistently met. These capabilities make industrial PCs a cornerstone of industrial applications, helping factories maintain efficiency and meet production goals.

Healthcare and Medical Equipment

Role in diagnostic machines and patient monitoring

In healthcare, industrial PCs serve as the backbone of diagnostic machines and patient monitoring systems. They process real-time data, enabling continuous monitoring of patients. For instance, they are integrated into MRI and CT scanners, ensuring quick data processing and high-quality imaging. Their ability to handle large data files efficiently makes them ideal for medical imaging applications like X-rays and ultrasounds. You’ll also find them in ventilators and other critical care equipment, where reliability is paramount.

Compliance with medical standards

Industrial PCs used in healthcare meet stringent medical standards. Many models feature antimicrobial housings to reduce the risk of infection spread. Their shock-resistant design ensures they can withstand vibrations, making them suitable for use in mobile medical units or ambulances. These features, combined with their ability to integrate seamlessly with existing medical systems, make them a trusted choice for healthcare professionals.

Defense and Aerospace

Applications in military-grade systems

Industrial PCs are essential in military-grade systems due to their durability and reliability. You can find them in mission-critical applications like radar systems, communication devices, and weapon control systems. Their rugged design allows them to endure extreme conditions, including high temperatures, shocks, and vibrations. This makes them a reliable choice for defense-related industrial applications.

Use in aircraft and space exploration

In aerospace, industrial PCs are integral to systems that require precision and reliability. They are used in aircraft for flight data recording, engine control, and navigation. In space exploration, these computers handle tasks like flight control, maintenance tracking, and communication management. Their ability to function in extreme conditions ensures they perform flawlessly in challenging environments, highlighting their importance in the aerospace sector.

Transportation and Logistics

Fleet management and tracking systems

Industrial PCs play a crucial role in fleet management and tracking systems. You can use them to monitor vehicle locations in real time, ensuring efficient route planning and timely deliveries. These systems also help you track fuel consumption and maintenance schedules, reducing operational costs. With their ability to process large amounts of data, industrial PCs enable you to optimize fleet performance and improve customer satisfaction. Their rugged design ensures reliable operation, even in vehicles exposed to constant vibrations and temperature changes.

Note: Industrial PCs integrate seamlessly with GPS and telematics systems, providing you with accurate data for better decision-making.

Use in railways and public transport

In railways and public transport, industrial PCs enhance safety and efficiency. You’ll find them managing ticketing systems, passenger information displays, and train control systems. These computers ensure smooth operations by monitoring train speeds, signaling systems, and track conditions. Their durability allows them to function reliably in harsh environments, such as outdoor stations or underground tunnels. By using industrial PCs, you can improve the overall travel experience for passengers while maintaining high safety standards.

Energy and Utilities

Monitoring power grids and renewable energy systems

Industrial PCs are indispensable in monitoring power grids and renewable energy systems. They help you track energy production and consumption in real time, ensuring a stable power supply. For renewable energy, these computers monitor wind turbines and solar panels, optimizing their performance. You can rely on industrial PCs to detect faults quickly, minimizing downtime and preventing power outages. Their ability to handle large-scale data processing makes them a vital component of modern energy management systems.

Use in oil and gas exploration

In oil and gas exploration, industrial PCs support critical operations.

They assist in well logging, providing you with detailed geological data.

Torque control systems rely on these computers for precision.

Downhole operations benefit from their robust performance.

Measurement-while-drilling (MWD) and directional drilling are made more efficient with industrial PCs.

Their rugged design ensures they withstand extreme conditions, such as high temperatures and pressures, making them ideal for this demanding industry.

Industrial computers are the backbone of modern industries, designed to handle harsh environments and demanding tasks. You benefit from their durability, reliability, and adaptability, which ensure continuous operation in critical applications. These systems excel in extreme conditions, offering superior performance and long lifespans compared to commercial PCs. Their customizable configurations and seamless integration with existing systems make them indispensable across sectors like manufacturing, healthcare, and energy. By investing in an industrial computer, you enhance efficiency, reduce downtime, and drive innovation in your operations.

FAQ

What makes industrial computers different from regular PCs?

Industrial computers are built for harsh environments. They feature rugged designs, extended lifespans, and high reliability. Unlike regular PCs, they resist extreme temperatures, dust, and vibrations. You can also customize them for specific industrial tasks, making them more versatile for demanding applications.

Can industrial computers be upgraded?

Yes, you can upgrade industrial computers. They are designed with scalability in mind, allowing you to add memory, storage, or new hardware. This ensures they remain relevant as your technology needs evolve, making them a future-proof investment.

Are industrial computers energy-efficient?

Many industrial computers are energy-efficient. They use fanless cooling systems and low-power components to reduce energy consumption. This design not only saves energy but also minimizes heat generation, ensuring reliable performance in demanding environments.

How long do industrial computers last?

Industrial computers typically last 7–15 years, depending on usage and maintenance. Their durable components and rugged construction ensure a longer lifespan compared to commercial PCs. Regular upkeep can further extend their operational life.

Which industries benefit most from industrial computers?

Industries like manufacturing, healthcare, transportation, and energy benefit greatly. You’ll find them in assembly lines, medical equipment, fleet management systems, and power grids. Their adaptability and reliability make them essential for critical operations across various sectors.

Tip: Choose an industrial computer tailored to your industry’s specific needs for optimal performance.