Top 10 PCB Manufacturers in China for 2025

Printed circuit boards (PCBs) are key to modern electronics. They are used in phones, computers, and medical tools. The PCB market is growing fast and may reach $84.24 billion by 2025. PCB China produces more than half of the world’s PCBs. Picking a good PCB maker in China means better quality and new ideas.

Key Takeaways

Picking a PCB maker with top certifications, like ISO 9001 and RoHS, guarantees good quality and safe production.

Knowing your project needs, like budget and delivery speed, helps you choose the best PCB maker for your goals.

Find makers with a history of few defects and happy customers to get dependable service.

Criteria for Ranking the Best PCB Manufacturers in China

Quality Standards and Certifications

When picking PCB makers in China, certifications show trustworthiness. These prove their processes follow global rules. Some important certifications include:

ISO 9001: Ensures strong quality management.

UL Certification: Confirms safety and reliability.

IPC Certifications: Sets key industry standards.

IATF 16949: Meets car industry needs.

RoHS Compliance: Limits harmful materials in production.

Top Chinese PCB companies make high-quality boards with over 99.5% success rates. Their focus on quality makes them reliable for industries like cars, planes, and gadgets.

Advanced Production Capacity and Technology

Chinese PCB companies are leaders in making and innovating. For example, Zhen Ding Technology makes over 2.5 million square meters of PCBs each month. They supply big brands like Apple and Huawei. These companies use advanced tech like HDI and multilayer PCBs. This helps them meet the need for smaller, more complex devices.

Manufacturer | Revenue (2020) | Production Capacity (sqm/month) | Major Customers |

|---|---|---|---|

Zhen Ding | $4.98 billion | Over 2.5 million | Apple, Huawei |

Shennan | $1.63 billion | Over 1 million | Ericsson, Bosch |

Reputation and Customer Feedback

A company’s reputation is important when choosing PCB suppliers. Many Chinese PCB makers, like JLCPCB and PCBCart, get great reviews. Customers praise their fast service, low prices, and good quality. They also deliver on time over 95% of the time. Companies that listen to feedback and improve keep more customers. This helps them stand out in the market.

Global Reach and Export Capabilities

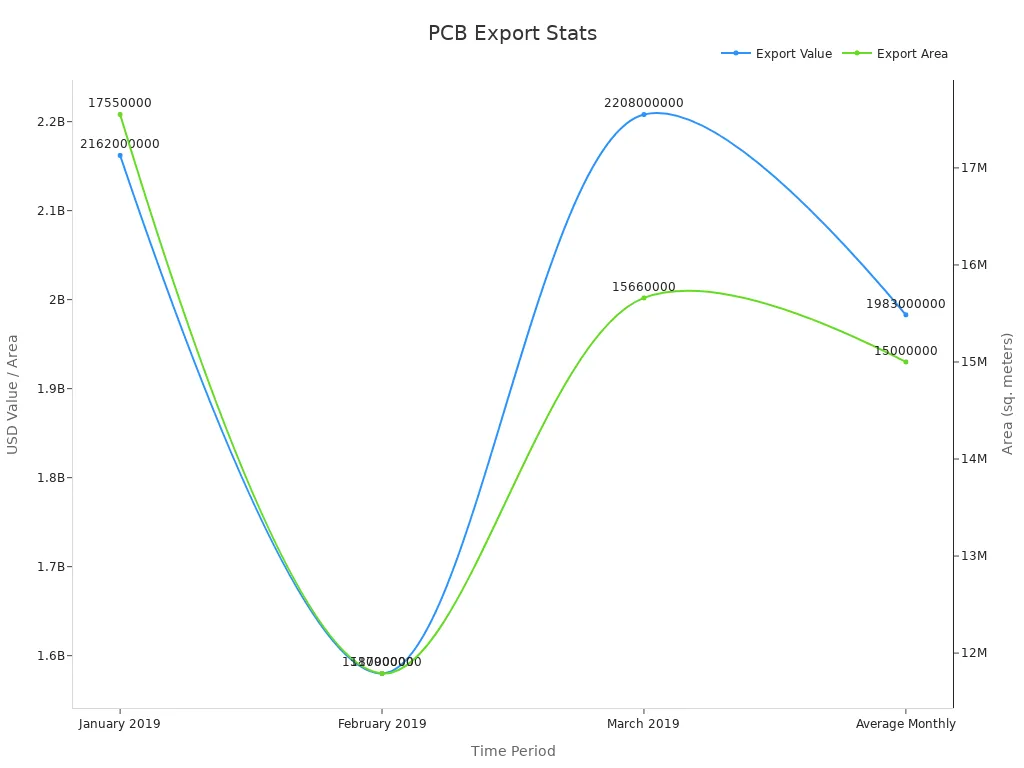

China leads the world in PCB production, making over half of all PCBs. In 2020, they exported 327.8 million square meters of PCBs. They meet global needs with certifications like IPC-6012 and ITAR. These allow them to serve industries from electronics to defense.

Chinese PCB makers use top materials and advanced methods to deliver great results. Their ability to serve global markets makes them a favorite for businesses everywhere.

Top 10 Chinese PCB Makers for 2025

Global Well Electronic Co., Ltd.

Global Well Electronic Co., Ltd. is a well-known PCB maker. They create high-quality boards for cars, phones, and electronics. Their advanced methods ensure accuracy and dependability. If you want a company focused on new ideas and happy customers, they are a great pick.

Avary Holding (Shenzhen) Co., Ltd.

Avary Holding is a top PCB producer in China. They are famous for their large factories and modern technology. Their boards are used in phones, laptops, and gadgets. Avary Holding cares about being eco-friendly and efficient, staying ahead in the industry.

Suzhou Dongshan Precision Manufacturing Co., Ltd.

Suzhou Dongshan Precision is skilled in flexible and rigid-flex PCBs. They work with industries like space, health, and cars. Their focus on quality and new designs has made them respected worldwide.

Viasion Technology Co., Ltd.

Viasion Technology is great for small to medium PCB orders. They deliver fast and provide excellent customer care. From simple to complex boards, Viasion offers good quality at fair prices.

Shennan Circuits Company Limited (SCC)

Shennan Circuits leads in making advanced, multilayer PCBs. They supply industries like defense and telecom. Their modern factories and strict checks make them perfect for tough projects.

How to Pick the Best PCB Manufacturer in China

Knowing Your Project Needs

Before choosing a PCB maker, know your project needs. Think about cost, delivery time, and material quality. For example, if you need prototype PCBs, pick a company offering fast prototyping services.

Follow these steps to get started:

Check your design, like layers and trace sizes.

Choose materials and set key parameters.

Share your quality rules to avoid confusion.

When you know your needs, you can find the right manufacturer.

Checking Manufacturer Skills and Experience

Not all PCB makers in China are equal. Look for companies with strong skills in PCB production. Check their certifications, factory size, and specialties. Top companies often have advanced tools and low defect rates.

Use these points to judge their skills:

Defect Rate: Lower rates mean better boards.

On-Time Delivery Rate: Shows they deliver quickly.

Customer Satisfaction Score: Tells you about their service.

A skilled manufacturer can handle tricky designs and save you money.

Confirming Certifications and Standards

Certifications are important when picking a PCB maker. Look for ISO 9001 for quality and RoHS for eco-friendly production. These prove the boards meet global rules.

Here’s a quick list:

Certification | What It Means |

|---|---|

ISO 9001 | Ensures good quality control. |

RoHS | Limits harmful materials. |

IATF 16949 | Meets car industry standards. |

Always check these certifications for trust and quality.

Comparing Prices, Delivery Times, and Options

Price and delivery time matter when picking a PCB maker. Some companies are great for fast PCBs, while others handle big orders. Compare prices and delivery times to find the best match.

For example:

Manufacturer | MOQ | Delivery Time | Price |

|---|---|---|---|

JLCPCB | Low | Fast | Cheap |

Viasion | Medium | Average | Fair |

Pick a company that offers good prices and quick delivery.

Looking at Customer Service and Support

Good customer service saves time and money. Choose companies with happy customers and helpful teams. After-sales support is key for prototype PCBs, as problems may happen during testing.

Signs of great service include:

Quick replies.

Clear answers.

Fixing issues fast.

A company with good support makes the process easier for you.

Picking the right PCB maker is very important for success. Top Chinese companies, like Shennan Circuits and Best Technology Co., Limited, are experts. They specialize in things like space-grade PCBs, fast prototypes, and advanced designs. Here's a simple table showing their key strengths:

Manufacturer Name | Key Strengths |

|---|---|

Best Technology Co., Limited | Great PCBs, fast prototypes, and assembly |

Shennan Circuits | Works with space, health, and telecom industries |

Suntak PCB | Makes precise circuit boards |

Victory Giant Technology | Creates top-quality PCBs for global clients |

To choose the best maker in China, match their skills to your needs. Think about things like material quality, how much they can produce, and their support. For example:

Customer Support: Fixes problems fast and keeps work on track.

Lead Time: Shorter times are better for urgent tasks.

Material Quality: Ensures strong and lasting products.

China leads in PCB making, with the market expected to hit $139.4 billion by 2024. This shows why picking a trusted supplier is so important. Check out the listed companies to find the best fit for your project.

FAQ

How long does it take to make PCBs in China?

Most companies need 5–10 days for regular PCBs. For prototypes, delivery can be as quick as 2–3 days.

How can I check if my PCB design works with the manufacturer?

Send your design files in formats like Gerber or ODB++. Make sure the company can handle your needs, like layers, materials, and trace sizes.

💡 Tip: Check your design carefully for mistakes before sending it. This helps avoid delays.

Can Chinese PCB makers handle small orders?

Yes, many focus on small-batch production. They offer good prices and fast service, perfect for prototypes or small projects.