How Sensor-Driven Robotic Milling Transforms Titanium Machining

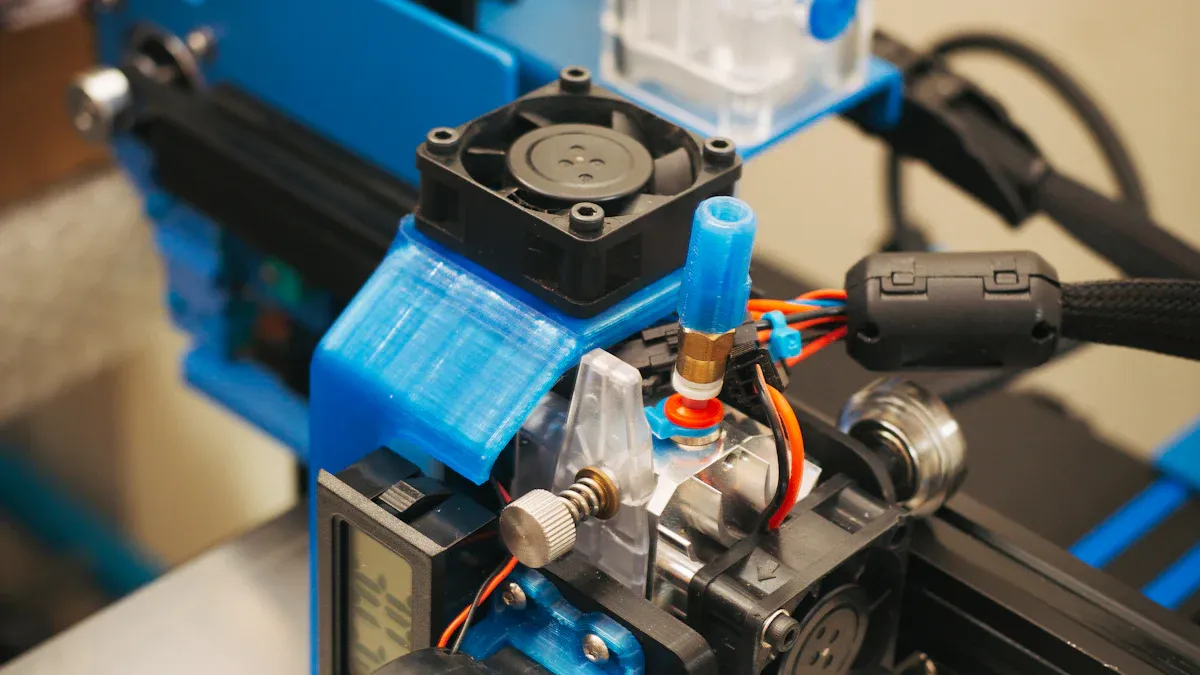

Sensor-driven robotic milling has revolutionized titanium machining by introducing unprecedented precision and adaptability. This technology uses real-time monitoring systems to make adjustments during machining, ensuring parameter optimization. By optimizing machining efficiency, it minimizes tool wear and improves surface quality. Robotic milling brings unmatched efficiency to industries working with titanium alloys, enhancing productivity and reliability.

Key Takeaways

Robots with sensors help cut titanium more accurately and smoothly. This lowers the number of mistakes.

These machines reduce tool damage and pauses, keeping work going and saving time.

Using sensor-guided robots boosts speed and saves money. It's useful for making airplane parts and medical tools.

Challenges in Machining Titanium

Titanium’s Unique Properties

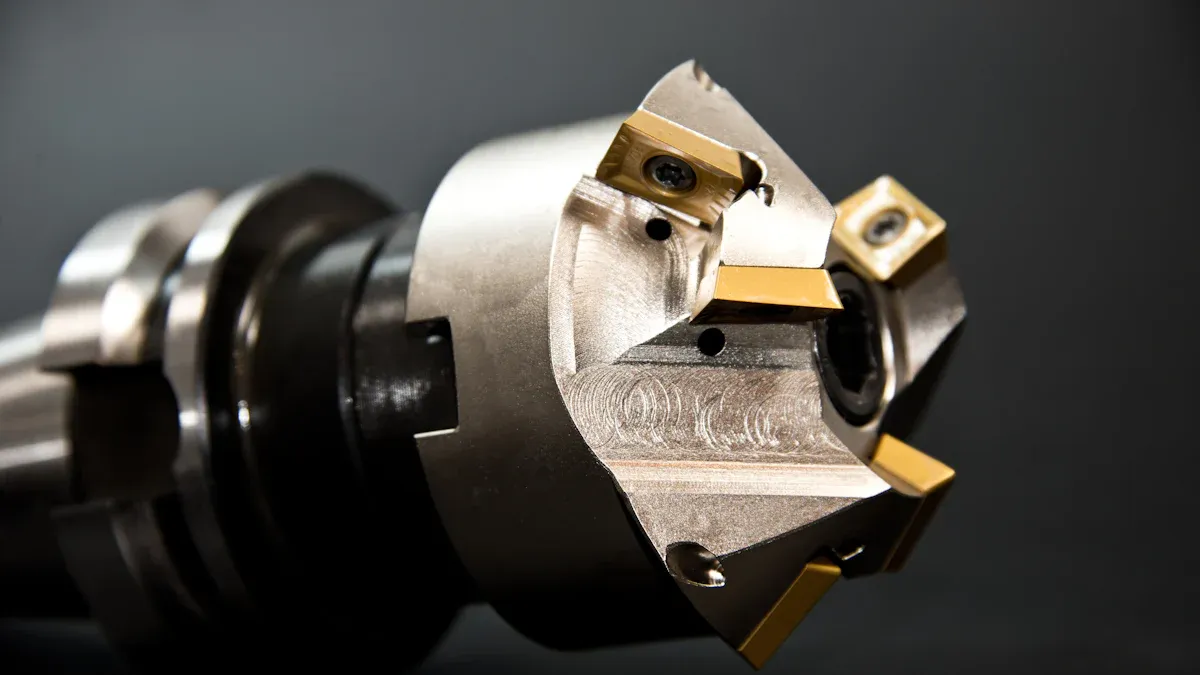

Titanium stands out due to its high strength-to-weight ratio and exceptional corrosion resistance, making it ideal for demanding applications. However, these advantages come with material-specific challenges during machining. Titanium alloys exhibit low thermal conductivity, which hinders heat dissipation and leads to significant heat buildup in the cutting zone. This heat generation accelerates tool wear and destabilizes the machining process. Additionally, titanium’s high hardness and strong chemical reactivity complicate cutting operations, often resulting in adverse interactions with cutting tools. These properties make titanium alloys notoriously difficult to machine, requiring advanced techniques to overcome operational challenges effectively.

Tool Wear and Heat Resistance Issues

Tool wear remains one of the most critical challenges in machining titanium. Studies on Ti-6Al-4V reveal that high thermal loads during machining rapidly degrade cutting tools, reducing their lifespan and productivity. Dry machining exacerbates this issue, as the absence of cooling intensifies heat buildup. Research highlights that cryogenic cooling can reduce tool wear by up to 33%, showcasing the importance of cooling methods in managing heat resistance. Coated tools also improve performance by minimizing wear. Despite these advancements, the inherent properties of titanium alloys continue to pose significant operational challenges, demanding constant innovation in machining techniques.

Inefficiencies in Traditional Methods

Traditional CNC machining techniques often struggle to address the complexities of titanium machining. Lower cutting speeds increase forces during milling, as thermal softening does not occur. Ultrasonic machining (USM) offers a promising alternative, reducing cutting time by at least 75% compared to conventional methods. USM also improves surface quality and reduces cutting forces by up to 50%. Electric discharge machining (EDM) provides high accuracy and better surface roughness without cutting forces, minimizing residual stress. While these methods show promise, traditional approaches remain inefficient for handling titanium’s unique properties, highlighting the need for sensor-driven solutions.

Benefits of Sensor-Driven Robotic Milling for Titanium Alloy Machining

Enhanced Precision and Surface Finish

Sensor-driven robotic milling significantly improves precision and surface finish in titanium alloy machining. By utilizing real-time monitoring systems, robotic machining adjusts cutting parameters dynamically, ensuring optimal performance. This approach minimizes defects and enhances the dimensional accuracy of titanium components.

A case study highlights the impact of robotic milling on defect rates. Before adopting sensor-driven techniques, the defect rate stood at 7.2%. After implementation, it dropped to 4.2%, representing a 42% improvement. Additional benefits include:

A 35% increase in first-pass yield.

A 28% reduction in rework time.

A 20% improvement in overall equipment effectiveness (OEE).

Surface finish quality also sees remarkable advancements. Titanium machining achieves an Ra value of less than 0.2 µm and precision tolerances of ±0.01 mm, ensuring smooth surfaces and tight dimensional control. These improvements make sensor-driven robotic milling indispensable for industries requiring high-quality titanium alloy components.

Reduced Tool Wear and Downtime

Robotic milling addresses one of the most persistent challenges in titanium alloy machining: tool wear. Titanium’s low thermal conductivity often leads to excessive heat buildup, which accelerates tool degradation. Sensor-driven systems mitigate this issue by optimizing cutting speeds and feed rates in real-time. This reduces thermal stress on tools and extends their lifespan.

By minimizing tool wear, robotic machining reduces downtime associated with tool replacement and maintenance. Manufacturers benefit from uninterrupted production cycles, enhancing overall efficiency. Additionally, advanced cooling techniques, such as cryogenic cooling, further improve tool performance during titanium machining. These innovations ensure that tools remain durable and reliable, even under demanding conditions.

Increased Productivity and Cost-Effectiveness

Sensor-driven robotic milling transforms titanium alloy machining into a highly productive and cost-effective process. Traditional CNC methods often struggle with inefficiencies caused by titanium’s unique properties. Robotic machining overcomes these challenges by leveraging real-time optimization to streamline operations.

Manufacturers experience faster machining cycles and reduced material waste. The ability to handle complex geometries with precision eliminates the need for extensive rework, saving both time and resources. Furthermore, the extended lifespan of tools reduces operational costs, making robotic milling a financially viable solution for titanium alloy manufacturing.

Industries such as aerospace, medical devices, and automotive benefit from these productivity gains. By adopting sensor-driven robotic milling, they achieve higher output rates while maintaining exceptional quality standards. This optimization ensures that titanium alloy machining meets the growing demands of modern manufacturing.

Industry Applications of Sensor-Driven Robotic Milling

Sensor-driven robotic milling has found widespread applications across industries that rely on titanium and its alloys. Its ability to deliver precision, efficiency, and adaptability makes it a transformative technology in sectors like aerospace, medical devices, and automotive manufacturing.

Aerospace: Optimized Lightweight Components

The aerospace industry demands lightweight yet durable components to enhance fuel efficiency and performance. Titanium alloys, with their exceptional strength-to-weight ratio, are ideal for this purpose. However, machining titanium for aerospace applications presents significant challenges due to its hardness and low thermal conductivity.

Sensor-driven robotic milling addresses these challenges by enabling real-time adjustments during machining. This ensures optimal cutting conditions, reducing tool wear and improving surface quality. For example, aerospace manufacturers use this technology to produce turbine blades, structural components, and fasteners with tight tolerances.

Note: The aerospace sector benefits from the precision and adaptability of robotic milling, which ensures consistent quality in titanium components. This technology also reduces material waste, contributing to sustainable manufacturing practices.

Medical Devices: Precision in Titanium Implants

The medical industry relies heavily on titanium for implants and surgical tools due to its biocompatibility and corrosion resistance. Precision is critical in medical applications, as implants must fit perfectly to ensure patient safety and comfort. Traditional CNC techniques often struggle to achieve the required accuracy and surface finish for medical-grade titanium components.

Sensor-driven robotic milling revolutionizes medical manufacturing by delivering unparalleled precision. Real-time monitoring systems adjust cutting parameters dynamically, ensuring flawless machining of titanium implants. This technology produces components with smooth surfaces and precise dimensions, reducing the need for post-processing.

A case study in medical device manufacturing revealed that robotic milling reduced defect rates by 30% and improved production efficiency by 25%. These advancements make it possible to meet the growing demand for high-quality titanium implants and surgical tools.

Automotive: High-Performance Titanium Alloy Parts

The automotive industry increasingly incorporates titanium alloys into high-performance parts to enhance vehicle strength and reduce weight. Components like exhaust systems, engine valves, and suspension springs benefit from titanium's unique properties. However, machining these parts requires advanced techniques to handle the material's hardness and heat resistance.

Sensor-driven robotic milling offers a solution by optimizing machining processes in real-time. This technology ensures consistent quality and reduces tool wear, even when working with complex geometries. Automotive manufacturers achieve faster production cycles and lower costs, making titanium alloy components more accessible for high-performance vehicles.

Tip: By adopting sensor-driven robotic milling, the automotive industry can meet the demand for lightweight, durable components while maintaining cost-effectiveness and efficiency.

Comparing Traditional Methods to Sensor-Driven Robotic Milling

Precision and Adaptability

Traditional CNC methods often struggle to achieve the precision required for machining titanium alloys. These methods rely on static programming, which limits their ability to adapt to real-time challenges. Sensor-driven robotic milling, however, excels in precision and adaptability. It continuously monitors machining conditions and adjusts parameters dynamically. This ensures consistent quality, even when working with titanium's unique properties.

Robotic milling operates continuously, enhancing productivity and reducing lead times. Its adaptability allows it to function effectively across various manufacturing environments. For instance, it excels in assembly lines, performing tasks with remarkable speed and accuracy. This capability streamlines operations and facilitates rapid design adjustments. Additionally, its versatility makes it suitable for custom or small-scale production, where precision and adaptability are critical.

Cost-Effectiveness and Longevity

Machining titanium alloys with traditional CNC techniques often results in high operational costs. Frequent tool wear and downtime for maintenance increase expenses. Sensor-driven robotic milling addresses these challenges by optimizing cutting speeds and feed rates in real-time. This reduces thermal stress on tools, extending their lifespan and minimizing replacement costs.

The extended durability of tools directly impacts cost-effectiveness. Manufacturers experience fewer interruptions, leading to higher efficiency and lower production costs. Furthermore, robotic milling's ability to handle complex geometries reduces material waste, contributing to overall savings. These advantages make it a financially sustainable choice for machining titanium alloys.

Handling Complex Geometries

Traditional CNC methods face significant challenges when machining intricate titanium components. The material's hardness and low thermal conductivity complicate the process, often requiring multiple setups and extensive rework. Sensor-driven robotic milling overcomes these limitations with advanced techniques.

This technology ensures precise machining of complex geometries by dynamically adjusting cutting parameters. It produces components with tight tolerances and smooth surfaces, eliminating the need for additional finishing. Robotic milling also accelerates the production of prototypes, enabling faster iterations during the design phase. Its ability to adapt to diverse tasks makes it indispensable for industries requiring high-performance titanium alloy parts.

About Evsint

Company Overview

Evsint stands as a leader in advanced manufacturing technologies. The company specializes in sensor-driven robotic milling solutions, transforming industries that rely on titanium machining. Its innovative approach addresses the challenges of working with titanium alloys, ensuring precision and efficiency in production. Evsint collaborates with aerospace, medical device, and automotive manufacturers to deliver cutting-edge solutions tailored to their needs.

Mission Statement

Evsint’s mission focuses on empowering industries through innovation. The company strives to redefine titanium machining by integrating sensor-driven technologies that enhance productivity and reduce operational costs. Its commitment to excellence drives the development of solutions that meet the evolving demands of modern manufacturing.

Note: Evsint prioritizes sustainability by designing systems that minimize material waste and energy consumption. This aligns with its goal of creating environmentally responsible manufacturing processes.

Vision for Innovation

Evsint envisions a future where manufacturing achieves unparalleled precision and adaptability. The company invests in research and development to advance sensor-driven robotic milling technologies. Its vision includes expanding applications of titanium machining across diverse industries, enabling manufacturers to produce complex components with ease.

Evsint also aims to foster collaboration with global partners to accelerate innovation. By sharing expertise and resources, the company seeks to drive progress in manufacturing technologies. This forward-thinking approach positions Evsint as a pioneer in transforming titanium machining for the next generation of industrial advancements.

Sensor-driven robotic milling transforms titanium machining by addressing its challenges and enhancing efficiency. Industries like aerospace, medical devices, and automotive benefit from improved product quality and precision. Businesses adopting this technology gain a competitive edge while optimizing production processes. This innovation ensures titanium machining meets modern manufacturing demands.

FAQ

What makes sensor-driven robotic milling better than traditional CNC methods?

Sensor-driven robotic milling offers real-time adjustments, improving precision, reducing tool wear, and handling complex geometries. These features make it more efficient and cost-effective than traditional CNC methods.

Can sensor-driven robotic milling handle small-scale production?

Yes, it excels in small-scale production. Its adaptability ensures precision and efficiency, making it ideal for custom manufacturing or prototyping titanium components.

How does this technology benefit industries using titanium alloys?

Industries gain higher productivity, reduced material waste, and improved product quality. Aerospace, medical, and automotive sectors benefit significantly from its precision and efficiency.

Tip: Businesses adopting sensor-driven robotic milling can stay competitive by meeting modern manufacturing demands with optimized processes.