PCB Assembly and PCB Fabrication Key Differences

Printed circuit boards (PCBs) form the backbone of modern electronics. PCB fabrication focuses on creating the physical structure of the board, transforming raw materials into a durable platform for circuits. On the other hand, PCB assemble brings the board to life by attaching electronic components, enabling it to perform specific functions. While fabrication builds the foundation, PCB assemble completes the process by making the board functional. Together, these processes drive the electronics industry, which continues to grow rapidly due to increasing demand for devices like smartphones and IoT gadgets.

Key Takeaways

PCB fabrication creates the physical structure of the board, while PCB assembly integrates electronic components to make it functional.

Understanding the distinct processes of fabrication and assembly helps you make informed decisions for your electronics projects.

Evaluate your project requirements to determine whether you need a bare PCB for testing or a fully assembled board for functionality.

Consider budget and timeline when choosing between fabrication and assembly, as costs can vary significantly based on complexity and methods used.

Collaboration between fabrication and assembly teams is crucial for ensuring quality and efficiency in the production process.

Working with reliable manufacturers that offer both fabrication and assembly services can streamline your project and enhance results.

Utilizing advanced technologies and automation in both processes improves precision and reduces production time, leading to higher quality outcomes.

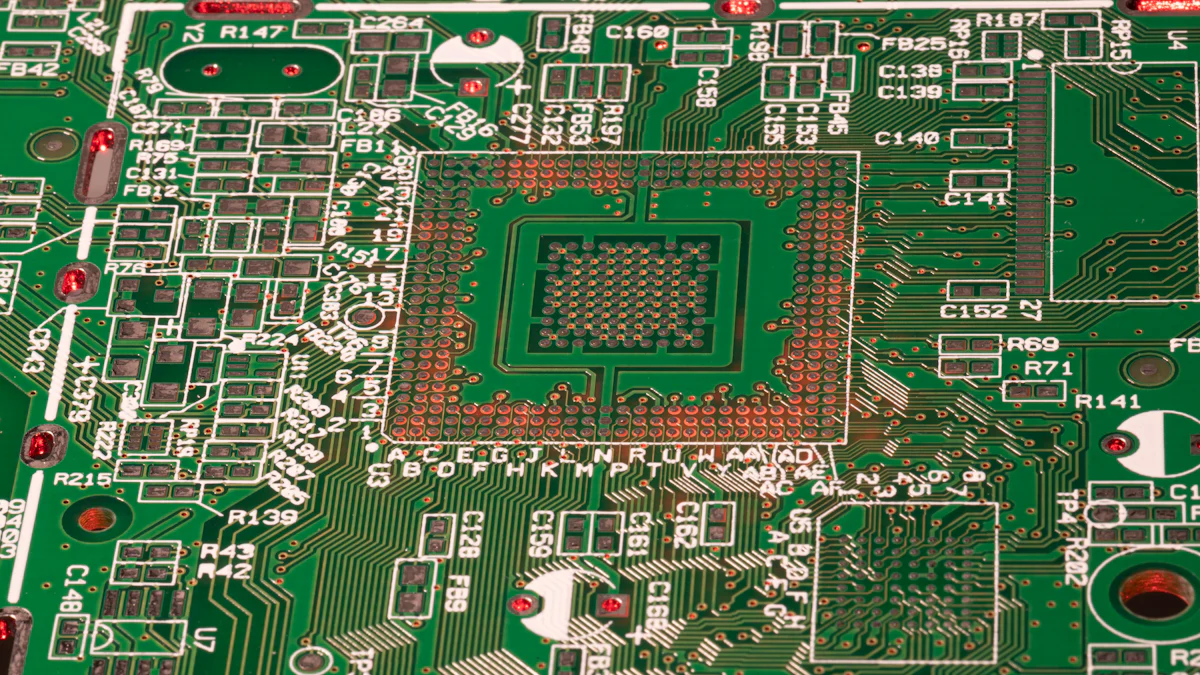

What Is PCB Assembly?

Printed circuit board assembly, often referred to as PCB assembly, is the process that transforms a bare PCB into a functional electronic device. This step involves attaching various electronic components, such as resistors, capacitors, and integrated circuits, onto the board. By doing so, you enable the board to perform its intended functions. The PCB assembly process is a critical phase in electronics manufacturing, as it breathes life into the fabricated boards.

Definition and Overview

PCB assembly focuses on integrating electronic components onto the surface of a printed circuit board. This process ensures that the board can operate as designed. It involves precise techniques and tools to achieve high-quality results. Automation plays a significant role in modern PCB assembly, with machines like pick-and-place systems and reflow soldering ovens ensuring accuracy and efficiency. However, certain tasks, such as manual inspection and through-hole component placement, still require human expertise.

Key Steps in the PCB Assembly Process

The PCB assembly process consists of several essential steps. Each step contributes to the overall functionality and reliability of the final product.

Solder Paste Application

The process begins with applying solder paste to the PCB. A stencil is used to deposit the paste onto specific areas where components will be placed. The solder paste contains a mixture of solder alloy and flux, which helps create strong connections between the board and the components.

Component Placement

After applying the solder paste, components are placed onto the board. Automated pick-and-place machines handle this task with precision, positioning each component in its designated location. These machines ensure consistency and speed, especially for surface-mounted components.

Reflow Soldering

Once the components are in place, the board undergoes reflow soldering. During this step, the board passes through a reflow oven, where controlled heat melts the solder paste. This process secures the components to the PCB, forming reliable electrical connections.

Inspection and Testing

The final step involves inspecting and testing the assembled PCB. Automated optical inspection (AOI) systems check for defects, such as misaligned components or poor solder joints. Functional testing ensures that the board operates as intended. Any issues identified during this stage are addressed to maintain quality.

Common Applications of PCB Assembly

PCB assembly is essential in creating functional electronic devices. You can find assembled PCBs in a wide range of applications, including:

Consumer Electronics: Smartphones, laptops, and wearable devices rely on PCB assembly for their functionality.

Automotive Industry: Modern vehicles use assembled PCBs for systems like navigation, sensors, and engine control.

Medical Devices: Equipment such as heart monitors and imaging systems depend on reliable PCB assembly.

Industrial Equipment: Assembled PCBs power machinery, robotics, and control systems in industrial settings.

By understanding the PCB assembly process, you gain insight into how electronic devices come to life. This knowledge helps you appreciate the complexity and precision required to produce high-quality electronics.

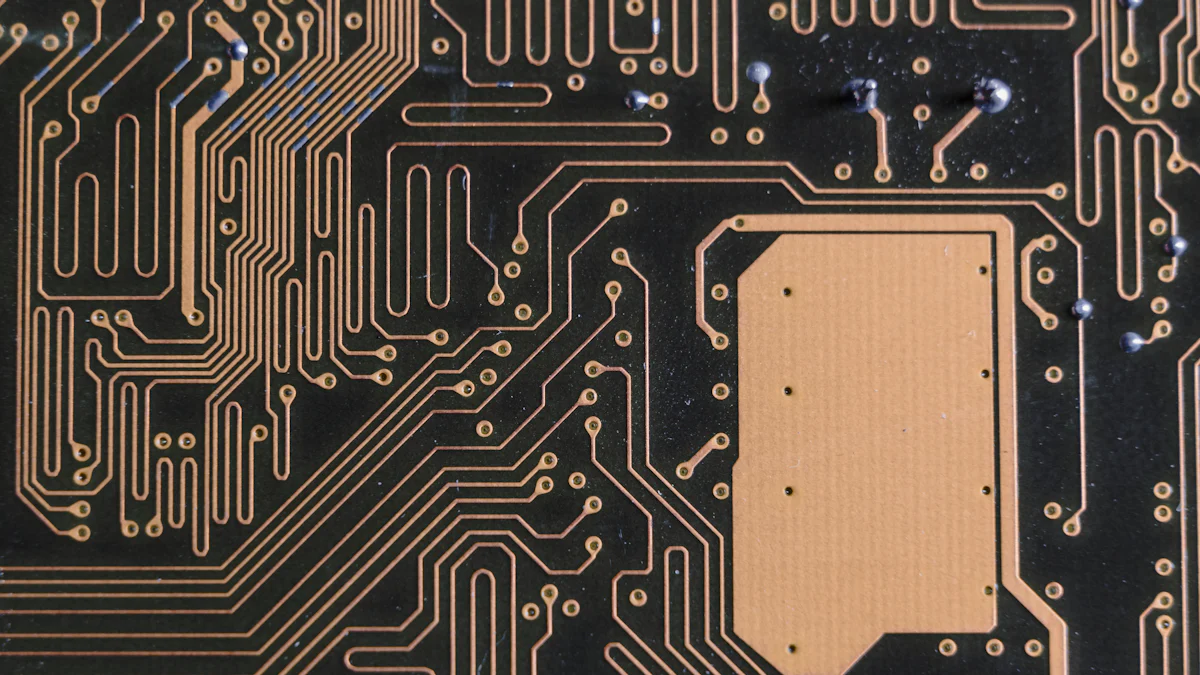

What Is PCB Fabrication?

Printed Circuit Board (PCB) fabrication is the process of transforming raw materials into the physical structure of a PCB. This process creates the foundation for electronic circuits, enabling the integration of components during assembly. PCB fabrication involves precise techniques to ensure the board meets design specifications and functions reliably. It plays a critical role in electronics manufacturing, as it establishes the framework for power distribution and signal routing.

Definition and Overview

PCB fabrication focuses on creating the bare board that serves as the backbone of electronic devices. This process begins with a schematic diagram and ends with a tangible board ready for assembly. Manufacturers use advanced technologies like High-Density Interconnect (HDI) and flexible PCBs to meet the growing demand for compact and high-performance electronics. These innovations allow you to achieve greater functionality while reducing the size of your devices.

The fabrication process ensures that the PCB can handle the electrical requirements of your design. It involves layering, etching, and other steps to create conductive pathways and insulating layers. By following precise design rules, manufacturers produce boards that support complex circuits and maintain reliability under various conditions.

Key Steps in the PCB Fabrication Process

The PCB fabrication process consists of several essential steps. Each step contributes to the creation of a durable and functional board.

Designing the PCB Layout

The process begins with designing the PCB layout. You use specialized software to create a schematic diagram that defines the placement of components and the routing of electrical connections. This step ensures that the board meets your design requirements and adheres to industry standards.

Layering and Etching

After finalizing the layout, manufacturers create the board's layers. They laminate copper sheets onto a substrate material and apply a protective mask. Etching removes excess copper, leaving behind the desired circuit patterns. This step forms the conductive pathways that enable electrical signals to flow through the board.

Drilling and Plating

Drilling creates holes for mounting components and establishing connections between layers. Manufacturers use precision drilling machines to achieve accurate hole placement. After drilling, they apply a plating process to coat the holes with conductive material, ensuring reliable electrical connections.

Solder Mask and Silkscreen Application

The final steps involve applying a solder mask and silkscreen. The solder mask protects the board's surface from oxidation and prevents solder bridges during assembly. The silkscreen adds labels and markings, helping you identify components and connections on the board. These finishing touches enhance the board's functionality and usability.

Common Applications of PCB Fabrication

PCB fabrication is essential for producing the boards used in various industries. You can find fabricated PCBs in:

Consumer Electronics: Devices like smartphones, tablets, and gaming consoles rely on fabricated PCBs for their core functionality.

Automotive Systems: Modern vehicles use PCBs for engine control units, infotainment systems, and safety features.

Medical Equipment: Fabricated PCBs power diagnostic tools, monitoring devices, and imaging systems.

Industrial Machinery: PCBs support automation, robotics, and control systems in manufacturing environments.

Understanding the PCB fabrication process helps you appreciate the complexity involved in creating the foundation for electronic devices. This knowledge enables you to make informed decisions when selecting manufacturers or designing your own PCBs.

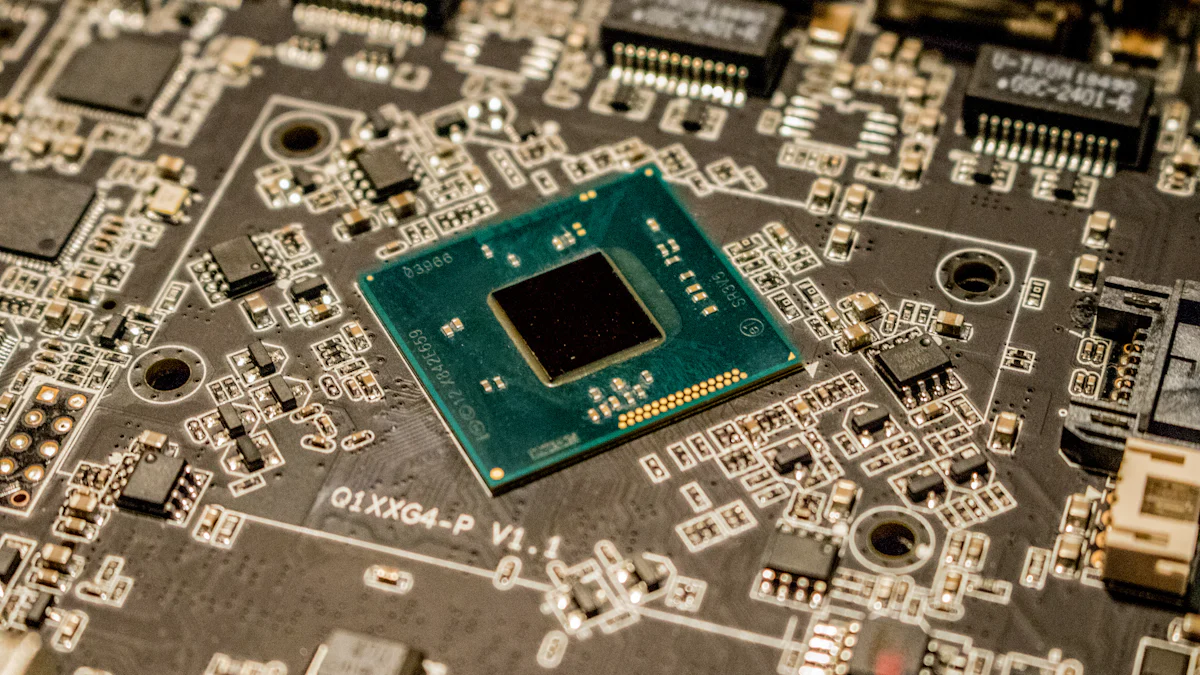

PCB vs PCBA: Key Differences

Understanding the differences between PCB and PCBA is essential for anyone involved in electronics manufacturing. While both terms are closely related, they represent distinct stages in the production process. Let’s explore how they differ in terms of process, cost, and functionality.

Process Differences

PCB fabrication focuses on creating the physical structure of the board. This process transforms raw materials into a durable platform for circuits. It involves steps like imaging, etching, drilling, and plating. These steps ensure the board meets design specifications and can handle electrical signals effectively.

In contrast, PCB assembly brings the fabricated board to life. During this stage, components such as resistors, capacitors, and microchips are soldered onto the board. This step integrates the electronic parts, enabling the board to perform its intended functions. While fabrication builds the foundation, assembly completes the product.

Cost Differences

The cost of PCB fabrication depends on several factors. Materials, the number of layers, and the complexity of the design all influence the price. For example, a multi-layer board with advanced features like High-Density Interconnect (HDI) will cost more than a simple single-layer board.

PCB assembly costs, on the other hand, vary based on the type and quantity of components. Surface-mounted components often require automated pick-and-place machines, which can increase costs. Additionally, the assembly method—whether manual or automated—affects the overall expense. Choosing the right balance between quality and budget is crucial for both processes.

Functional Differences

Fabrication produces the bare board, which serves as the backbone of any electronic device. Without this structure, there would be no platform to support circuits or components. The fabrication process ensures the board can handle electrical requirements and maintain durability.

Assembly, however, transforms the board into a functional device. By attaching components, you enable the board to perform tasks like processing data, powering devices, or controlling systems. While fabrication lays the groundwork, assembly ensures the board fulfills its purpose.

By understanding these key differences, you can make informed decisions when planning your electronics project. Whether you need a bare board or a fully assembled product, knowing the distinctions between PCB and PCBA will guide you in choosing the right service.

Application Differences

Fabrication is used in prototyping and mass production of PCBs.

PCB fabrication plays a vital role in the early stages of electronic product development. When you need to test a new design, fabrication allows you to create prototype boards that help validate your ideas. These prototypes ensure that your circuit functions as intended before moving to the next phase. By using fabrication for prototyping, you can identify and fix design flaws early, saving time and resources.

In addition to prototyping, fabrication supports mass production. Manufacturers rely on this process to produce large quantities of printed circuit boards with consistent quality. The fabrication process involves steps like imaging, etching, drilling, and plating, which transform raw materials into durable boards. These boards serve as the foundation for electronic devices across various industries. Whether you are developing consumer electronics or industrial machinery, fabrication ensures that your PCBs meet design specifications and performance standards.

Assembly is used in creating functional electronic devices.

PCB assembly takes the fabricated board and turns it into a working electronic device. This process involves attaching components like resistors, capacitors, and microchips to the board. By soldering these parts onto the PCB, you enable it to perform specific tasks, such as processing data or controlling systems. Assembly bridges the gap between a bare board and a fully functional product.

You will find assembled PCBs in countless applications. Consumer electronics like smartphones and laptops depend on assembly to function. In the automotive industry, assembled boards power navigation systems, sensors, and engine controls. Medical devices, including heart monitors and imaging equipment, also rely on assembly for precision and reliability. Without this process, the fabricated boards would remain incomplete and unable to fulfill their purpose.

By understanding the distinct applications of fabrication and assembly, you can better plan your electronics projects. Fabrication provides the structural base, while assembly brings the board to life. Together, these processes ensure that your designs evolve into reliable and functional products.

How PCB Assembly and PCB Fabrication Relate to Each Other

Sequential Relationship

PCB fabrication and assembly follow a clear sequence, each playing a distinct role in the production of electronic devices. Fabrication always comes first. During this stage, you create the physical structure of the printed circuit board. This involves processes like layering, etching, and drilling, which transform raw materials into a durable platform for circuits. The fabricated board serves as the foundation for all subsequent steps.

Once the board is fabricated, assembly begins. In this phase, you attach electronic components such as resistors, capacitors, and microchips to the board. This step transforms the bare PCB into a functional product capable of performing specific tasks. Without fabrication, there would be no board to assemble. Without assembly, the board would remain an inert structure. Together, these processes ensure that your design evolves into a fully operational electronic device.

Importance of Collaboration

Collaboration between fabrication and assembly teams is essential for achieving high-quality results. Design considerations must align across both processes. For example, when designing your PCB layout, you need to account for factors like component placement, soldering points, and thermal management. These details directly impact both the fabrication and assembly stages. A well-thought-out design ensures that the board can be fabricated accurately and assembled efficiently.

Effective communication between the two teams also plays a critical role. If you work with separate manufacturers for fabrication and assembly, you must ensure that both parties understand your project requirements. Some manufacturers offer in-house services for both processes, simplifying coordination. Others may outsource assembly to a partner, requiring you to send your fabricated boards and components to an assembler. In such cases, clear communication prevents errors and delays.

For designers unfamiliar with procurement or consignment, turnkey services can be a valuable option. These services handle everything from fabrication to assembly, allowing you to focus on your design. By fostering collaboration and choosing the right manufacturing approach, you can streamline the production process and ensure the success of your project.

Tips for Choosing Between PCB Assembly and Fabrication

Understand Your Project Requirements

Before starting your project, you need to clearly define your requirements. Determine whether your project demands a bare PCB or a fully assembled board. A bare PCB serves as the foundation for circuits, while an assembled board includes all necessary electronic components, making it functional. If your goal is prototyping or testing a design, a fabricated PCB might suffice. However, for a complete product ready for use, you will need assembly to integrate components and ensure functionality.

Pro Tip: Evaluate the complexity of your design. If it involves intricate circuits or advanced features, opting for assembly ensures that the board meets your performance expectations.

Consider Budget and Timeline

Budget and timeline play a significant role in deciding between fabrication and assembly. PCB fabrication costs depend on factors like materials, the number of layers, and design complexity. For instance, a multi-layer board with advanced features will cost more than a simple single-layer board. On the other hand, assembly costs vary based on the type and quantity of electronic components, as well as the assembly method used.

Automated processes, such as pick-and-place machines and reflow soldering ovens, can speed up assembly and reduce labor costs. However, manual tasks like through-hole component insertion and quality testing may increase expenses. Assess your budget and project deadlines carefully to choose the most suitable option.

Quick Tip: If you are working on a tight timeline, consider manufacturers that offer turnkey services. These providers handle both fabrication and assembly, saving you time and effort.

Work with Reliable Manufacturers

Choosing a reliable manufacturer ensures the success of your project. Look for providers with expertise in both fabrication and assembly. Experienced manufacturers use advanced equipment, such as CNC machines and automated testing systems, to deliver high-quality results. They also follow strict quality testing protocols to ensure that your boards meet industry standards.

When selecting a manufacturer, check their track record and customer reviews. Reliable providers often offer comprehensive services, including design support, fabrication, assembly, and testing. This integrated approach minimizes errors and streamlines the production process.

Expert Insight: Automation enhances precision and efficiency in both fabrication and assembly. However, manual inspection and troubleshooting remain essential for maintaining quality.

By understanding your project needs, evaluating costs and timelines, and partnering with a trusted manufacturer, you can make informed decisions. These steps will help you achieve a successful outcome, whether you require a bare PCB or a fully assembled board.

Understanding the differences between PCB assembly and PCB fabrication is crucial for successful electronic production. Fabrication creates the physical board, while assembly transforms it into a functional device. Both processes require precision and expertise to ensure quality. By assessing your project needs, budget, and timeline, you can determine the right service for your goals. Collaborating with reliable manufacturers simplifies the process and enhances results. Whether you need a bare PCB or a fully assembled product, making informed decisions ensures your electronic devices meet performance expectations.

FAQ

What is the difference between PCB and PCBA?

A PCB refers to the bare printed circuit board, which contains the physical structure and circuitry but lacks electronic components. PCBA, or Printed Circuit Board Assembly, involves attaching components like resistors, capacitors, and microchips to the PCB, transforming it into a functional device. Understanding this distinction helps you determine whether you need just the board or a fully assembled product for your project.

How do I choose the right PCB manufacturer?

Selecting the right PCB manufacturer requires careful evaluation. Look for manufacturers with ISO 9001 certification, as this ensures adherence to quality standards. Visit their facility if possible to assess their technical capabilities and equipment. Evaluate their customer support and communication to ensure they can meet your specific needs. A reliable manufacturer prioritizes quality and offers flexibility in handling complex designs.

What factors affect the cost of PCB fabrication?

The cost of PCB fabrication depends on several factors. The materials used, the number of layers, and the complexity of the design all play a role. For instance, multi-layer boards or those with advanced features like High-Density Interconnect (HDI) will cost more than simple single-layer boards. By understanding these factors, you can better plan your budget and choose the right options for your project.

Why is PCB assembly more expensive than fabrication?

PCB assembly often costs more due to the complexity of attaching components. The type and quantity of components, as well as the assembly method, influence the price. Automated processes like pick-and-place machines and reflow soldering ovens improve efficiency but add to the cost. Manual tasks, such as through-hole component placement, also increase expenses. Investing in quality assembly ensures your device functions reliably.

Can one manufacturer handle both PCB fabrication and assembly?

Yes, many manufacturers offer turnkey services that include both fabrication and assembly. This approach simplifies the production process by reducing the need for coordination between separate providers. Turnkey services also ensure better communication and alignment between the two stages, resulting in higher-quality outcomes. Choosing a single provider for both processes can save you time and effort.

What should I consider when designing a PCB for fabrication?

When designing a PCB, follow Design for Manufacturing (DFM) rules to ensure smooth fabrication. Pay attention to component placement, trace width, and spacing to meet industry standards. Use specialized software to create accurate layouts and avoid errors. A well-designed PCB minimizes production issues and ensures the final product meets your quality expectations.

How can I ensure the quality of my PCB assembly?

To ensure quality in PCB assembly, work with experienced manufacturers who use advanced equipment and follow strict testing protocols. Automated Optical Inspection (AOI) systems and functional testing help identify defects early. Choose a manufacturer with a proven track record of delivering reliable assemblies. Quality assembly ensures your device performs as intended and lasts longer.

What are the common applications of fabricated PCBs?

Fabricated PCBs serve as the foundation for various electronic devices. You’ll find them in consumer electronics like smartphones and gaming consoles, automotive systems such as engine controls and sensors, and medical equipment like diagnostic tools. Fabrication provides the structural base needed for these devices to function effectively.

Why is collaboration between fabrication and assembly teams important?

Collaboration ensures that the design aligns with both fabrication and assembly requirements. For example, proper component placement and soldering points must be considered during the design phase. Effective communication between teams prevents errors, reduces delays, and improves the overall quality of the final product. Working with manufacturers that handle both processes in-house can simplify this collaboration.

How do I decide between PCB fabrication and assembly for my project?

Your decision depends on your project’s requirements. If you need a prototype or a bare board for testing, PCB fabrication might suffice. For a complete, functional product, you’ll need PCB assembly to integrate components. Consider your budget, timeline, and the complexity of your design to make the right choice. Consulting with a reliable manufacturer can also help you decide.