Understanding the Features and Benefits of Industrial Edge Computing Gateways

Industrial edge computing gateways serve as essential devices in modern industrial and IoT systems. These gateways enable data processing and analysis directly at the edge of networks, reducing dependency on centralized data centers. This approach ensures faster decision-making and improved system efficiency.

The adoption of industrial edge computing gateways is rapidly growing worldwide:

The global market is expected to grow at a compound annual growth rate of over 20% from 2023 to 2030.

By 2030, the market size will reach several billion dollars.

North America leads in revenue, while Asia Pacific shows the fastest growth due to industrialization in countries like China and India.

Devices like the EG5120 exemplify the transformative potential of these gateways, offering robust features for real-time applications.

Key Takeaways

Industrial edge gateways help work faster by handling data nearby. This cuts delays and helps make better choices quickly.

They process data in real-time, which lowers waiting time. This is very useful for things like healthcare and transportation that need quick actions.

Strong security tools, like data scrambling and user controls, keep important information safe and systems secure in factories.

These gateways can grow with more data and work with old systems. This makes them useful for many different jobs.

Using edge gateways saves money by using resources wisely. They also predict problems early, helping machines last longer.

Key Features of Industrial Edge Computing Gateways

Hardware Capabilities

Industrial edge gateways are equipped with advanced hardware designed to meet the demands of modern industrial environments. These devices feature robust processors, such as ARM Cortex-A53 quad-core CPUs, which provide the computational power necessary for real-time analytics and decision-making. Connectivity options, including 4G LTE, Wi-Fi, and Bluetooth, ensure seamless integration with existing systems and IoT networks.

Tip: Hardware durability is crucial for industrial settings. Many edge gateways, like the EG5120, feature rugged designs with IP-rated enclosures and wide operating temperature ranges to withstand harsh conditions.

The table below highlights key performance metrics that demonstrate the hardware capabilities of industrial edge gateways:

Metric Type | Description |

|---|---|

Connectivity | Ensures connectivity among industry networks and legacy devices, enabling data collection and monitoring. |

Real-Time Processing | Allows for low-latency decision-making and immediate action on anomalies to prevent equipment failure. |

Condition Monitoring | Enables tracking of equipment health, facilitating condition-based and predictive maintenance strategies. |

Production Monitoring | Provides real-time insights into production performance, allowing for immediate problem resolution and optimization. |

These features make edge gateways indispensable for industries aiming to optimize operations and reduce downtime.

Software and Operating Systems

The software capabilities of industrial edge gateways play a pivotal role in their functionality. These devices often run lightweight operating systems optimized for edge computing, such as Linux-based platforms. Support for containerized applications, like Docker, enables efficient deployment and management of software solutions.

Edge gateways also support a wide range of industrial protocols, including MQTT and fieldbus protocols, ensuring compatibility with diverse IoT systems. Advanced software features, such as centralized device management platforms, allow users to monitor performance, perform over-the-air updates, and troubleshoot issues remotely.

Note: The Robustel EG5120 integrates seamlessly with the Robustel Cloud Manager Service (RCMS), providing users with real-time device monitoring and management capabilities. This feature enhances operational efficiency and reduces maintenance costs.

Real-Time Data Processing

Real-time data processing is a defining feature of industrial edge gateways. These devices analyze sensor data immediately, enabling quick identification of equipment anomalies and preventing breakdowns. This capability significantly reduces downtime and enhances operational efficiency.

In industrial environments, edge analytics achieve over 50% reduction in latency compared to traditional cloud-based approaches. This improvement is particularly beneficial for applications requiring immediate decision-making, such as traffic management and emergency responses.

Benefits of real-time data processing include:

Reduced latency for critical applications

Improved bandwidth efficiency

Enhanced data privacy

Real-time data processing allows industries to respond to anomalies faster.

It optimizes resource utilization by processing data locally.

It ensures sensitive data remains secure by minimizing cloud dependency.

Edge gateways, like the EG5120, exemplify the efficiency of real-time data processing, making them essential for modern industrial operations.

Security and Data Protection

Industrial edge computing gateways prioritize security and data protection to safeguard sensitive information and ensure system integrity. These devices operate in environments where cyber threats and unauthorized access can disrupt operations. To address these challenges, manufacturers incorporate advanced security measures into their designs.

Key security features include:

Encryption Protocols: Gateways use encryption to protect data during transmission. This ensures that sensitive information remains secure, even when transmitted over public networks.

Secure Boot: This feature prevents unauthorized software from running on the device by verifying the integrity of the operating system during startup.

Firewall and Intrusion Detection: Built-in firewalls and intrusion detection systems monitor network traffic and block malicious activities.

Role-Based Access Control (RBAC): RBAC restricts access to the device based on user roles, ensuring only authorized personnel can make changes.

Note: The Robustel EG5120 enhances data security by supporting secure communication protocols like MQTT over TLS. This ensures that data remains protected from interception or tampering.

In addition to these features, centralized management platforms, such as the Robustel Cloud Manager Service (RCMS), enable real-time monitoring of device security. These platforms allow administrators to detect vulnerabilities, apply patches, and perform updates remotely. By implementing these measures, industrial edge gateways provide a robust defense against cyber threats.

Scalability and Interoperability

Scalability and interoperability are critical for industrial edge computing gateways to adapt to evolving operational needs. These devices must handle increasing data volumes and integrate seamlessly with diverse systems and protocols.

Scalability:

Industrial operations often expand over time, requiring gateways to support additional devices and data streams. Scalable gateways, like the EG5120, accommodate growth without compromising performance. Features that enhance scalability include:

Modular Design: Modular hardware allows users to add components, such as additional storage or connectivity options, as needed.

Cloud Integration: Gateways that connect to cloud platforms can offload data processing tasks, ensuring consistent performance even as data volumes grow.

Interoperability:

Interoperability ensures that gateways can communicate with various devices, systems, and protocols. This capability is essential for industries using legacy equipment alongside modern IoT solutions. Key aspects of interoperability include:

Protocol Support: Gateways must support a wide range of industrial protocols, such as Modbus, MQTT, and OPC UA, to ensure compatibility with existing systems.

API Integration: Application Programming Interfaces (APIs) enable gateways to interact with third-party software and platforms, facilitating seamless data exchange.

Cross-Vendor Compatibility: Interoperable gateways work with devices from multiple manufacturers, reducing vendor lock-in and increasing flexibility.

Tip: The Robustel EG5120 excels in scalability and interoperability by supporting Docker containers and multiple industrial protocols. This makes it suitable for diverse applications, from manufacturing to smart city initiatives.

By prioritizing scalability and interoperability, industrial edge computing gateways ensure long-term adaptability and seamless integration into complex industrial ecosystems.

Benefits of Industrial Edge Computing Gateways

Improved Operational Efficiency

Industrial edge computing gateways transform operational efficiency by enabling real-time data processing and local processing. These devices analyze information directly at the edge, reducing the need to send data to centralized systems. This approach minimizes delays and enhances decision-making capabilities.

Real-time insights from edge gateways allow industries to optimize processes and reduce waste. For example, manufacturers can monitor production lines to identify inefficiencies and adjust operations immediately. This proactive approach improves productivity and prevents costly downtime.

The impact of improved operational efficiency is evident in business performance. Companies that adopt edge computing gateways report significant reductions in waste and operational costs. By processing data locally, these devices streamline workflows and enhance resource utilization.

Tip: Real-time analytics at the edge empower industries to make faster decisions, ensuring smoother operations and better outcomes.

Enhanced Security and Data Privacy

Industrial edge computing gateways strengthen security and protect sensitive data. These devices process information locally, reducing exposure to external threats. By minimizing reliance on cloud systems, gateways ensure that critical data remains within the organization’s control.

Advanced security features, such as encryption protocols and secure boot mechanisms, safeguard data during transmission and storage. Role-based access control further enhances security by restricting access to authorized personnel. These measures prevent unauthorized access and protect against cyberattacks.

Local processing also contributes to data privacy. Sensitive information, such as customer details or proprietary data, stays within the local network. This reduces the risk of breaches and ensures compliance with data protection regulations.

Note: Industrial edge gateways, like the EG5120, integrate robust security protocols to protect data and maintain system integrity.

Reduced Latency for Real-Time Applications

Industrial edge computing gateways excel in reducing latency for real-time applications. By processing data locally, these devices eliminate the delays associated with transmitting information to remote servers. This capability is crucial for industries that rely on immediate responses, such as transportation and healthcare.

Real-time data processing enables faster detection of anomalies and quicker responses to emergencies. For instance, in traffic management systems, edge gateways analyze sensor data to adjust signals and prevent congestion. Similarly, in healthcare, these devices support remote monitoring by providing instant updates on patient conditions.

The reduction in latency also improves bandwidth efficiency. By handling data locally, gateways reduce the volume of information sent to external systems. This optimization ensures smoother operations and enhances overall system performance.

Callout: Real-time applications benefit significantly from edge gateways, as they enable faster responses and improved reliability.

Cost Savings and Resource Optimization

Industrial edge computing gateways offer significant cost savings by optimizing resource utilization and reducing operational expenses. These devices process data locally, minimizing the need for extensive cloud storage and bandwidth usage. This approach not only reduces costs but also enhances efficiency in industrial operations.

One of the primary ways edge gateways achieve cost savings is through predictive maintenance. By analyzing data from sensors in real time, these devices identify potential equipment failures before they occur. This proactive approach reduces unplanned downtime and extends the lifespan of industrial assets. For example, manufacturers can use edge gateways to monitor machinery performance, ensuring timely maintenance and avoiding costly repairs.

The table below highlights key aspects of cost savings and resource optimization enabled by industrial edge computing gateways:

Aspect | Description |

|---|---|

Bandwidth Costs | Reduction in data transmission to the cloud minimizes bandwidth expenses. |

Operational Expenses | Predictive maintenance and optimized resource utilization lead to lower operational costs. |

Asset Lifespan | Enhanced resource utilization prolongs the lifespan of assets, contributing to long-term savings. |

In addition to reducing costs, edge gateways improve productivity. Real-time data processing allows industries to optimize workflows and eliminate inefficiencies. For instance, in manufacturing, these devices enable precise monitoring of production lines, ensuring consistent quality and reducing waste. The convergence of IT and OT (Operational Technology) further streamlines operations, leading to enhanced business outcomes.

Callout: By processing data locally, industrial edge gateways reduce bandwidth usage and operational costs, making them a cost-effective solution for modern industries.

Increased System Reliability and Uptime

Industrial edge computing gateways play a crucial role in enhancing system reliability and uptime. These devices operate independently of centralized systems, ensuring continued functionality even during network disruptions. By processing data locally, edge gateways enable IoT devices to make decisions without relying on external servers.

The ability to operate autonomously improves overall system reliability. For example, in energy management systems, edge gateways monitor power grids in real time, detecting anomalies and preventing outages. Similarly, in transportation, these devices ensure uninterrupted operation of traffic management systems, even in areas with limited connectivity.

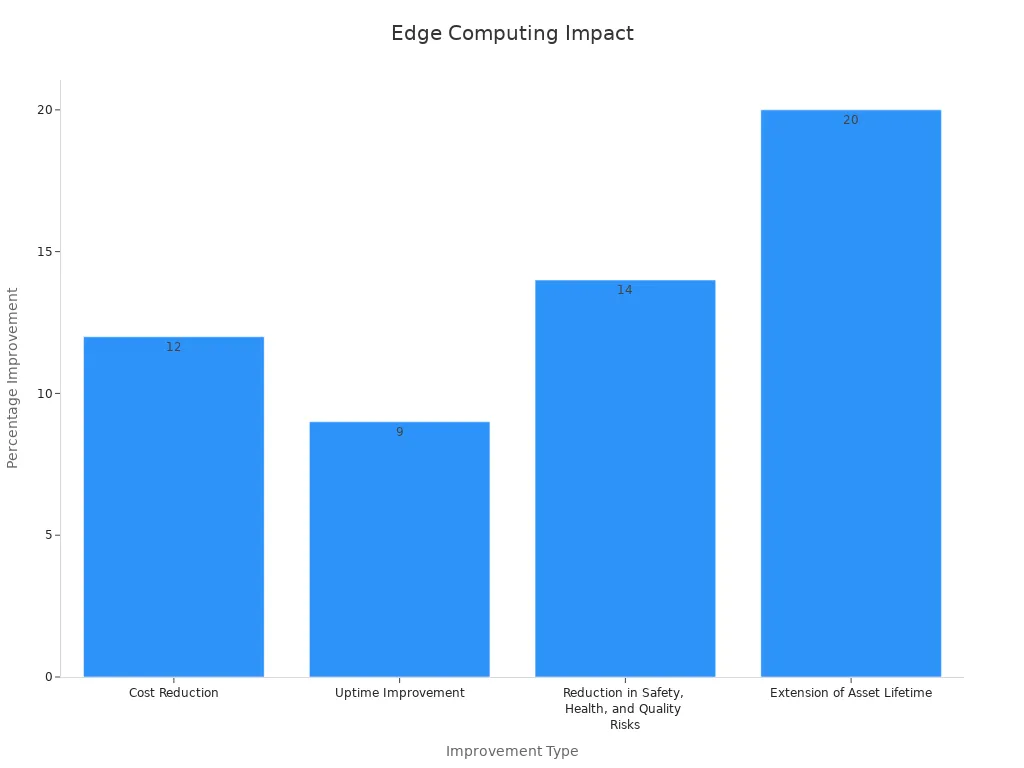

The chart below illustrates the percentage improvements in system reliability and uptime achieved through the implementation of industrial edge computing gateways:

Key improvements include:

A 9% increase in system uptime.

A 14% reduction in safety, health, and quality risks.

These improvements translate into tangible benefits for industries. Enhanced reliability reduces the risk of operational disruptions, while increased uptime ensures consistent productivity. Additionally, the ability to detect and address issues in real time minimizes safety risks and improves overall system performance.

Tip: Industrial edge gateways enhance reliability by enabling local decision-making, ensuring uninterrupted operations in critical applications.

Real-World Applications of Industrial Edge Computing Gateways

Manufacturing and Smart Factories

Industrial edge computing gateways play a pivotal role in transforming manufacturing into smart factories. These gateways enable real-time monitoring of production lines, ensuring optimal performance and reducing downtime. By processing data locally, they identify inefficiencies and equipment faults immediately, allowing manufacturers to take corrective actions without delays.

In aerospace manufacturing, sensitive data is processed locally to enhance security. This approach minimizes the risk of cyber threats while maintaining operational efficiency. Additionally, edge gateways reduce network load by sending only key performance indicators to the cloud. This bandwidth optimization ensures smooth operations even in data-intensive environments.

Smart factories also benefit from predictive maintenance capabilities. Edge gateways analyze machinery data to detect potential failures before they occur. This proactive approach extends equipment lifespan and prevents costly disruptions.

Energy and Utilities Management

In the energy sector, industrial edge computing gateways ensure efficient management of resources. These devices monitor power grids in real time, detecting anomalies and preventing outages. By processing data locally, they enable immediate decision-making, which is critical for maintaining system stability.

Remote oil and gas monitoring relies heavily on edge gateways. These devices continue to function even without cloud connectivity, ensuring uninterrupted operations in remote locations. Predictive maintenance further enhances reliability by providing alerts on equipment issues before they escalate.

Edge IoT platforms also optimize bandwidth usage by reducing the volume of data sent to the cloud. This approach lowers operational costs while improving efficiency. Companies in the utilities sector leverage these gateways to enhance system reliability and ensure consistent service delivery.

Transportation and Logistics

Transportation and logistics industries utilize industrial edge computing gateways to improve operational visibility and efficiency. Companies like FedEx and Maersk rely on these devices for real-time tracking and monitoring. For instance, FedEx uses SenseAwareID to track packages with minimal network load, while Maersk employs Remote Container Management to monitor container conditions and location data locally.

In logistics applications, edge gateways enable predictive maintenance for vehicles and equipment. This capability reduces downtime and ensures timely deliveries. DHL, for example, uses smart glasses integrated with edge computing to streamline inventory management, significantly reducing order fulfillment times.

Low latency is another advantage of edge gateways in transportation. By processing data at the edge, these devices enable real-time decision-making, which is crucial for mission-critical operations like traffic management and fleet optimization.

Healthcare and Remote Monitoring

Industrial edge computing gateways are revolutionizing healthcare by enabling real-time monitoring and data processing. These devices collect and analyze patient data from IoT-enabled medical devices, such as wearable sensors and remote monitoring systems. By processing data locally, they provide instant insights into patient health, allowing healthcare providers to respond quickly to emergencies.

Remote monitoring is particularly beneficial for managing chronic conditions. For instance, patients with diabetes or heart disease can use IoT devices to track vital signs. Edge gateways process this data in real time, alerting medical professionals to any irregularities. This proactive approach reduces hospital visits and improves patient outcomes.

In rural or underserved areas, edge gateways bridge the gap in healthcare access. They enable telemedicine solutions by ensuring reliable data transmission and low latency. For example, doctors can remotely monitor patients and make informed decisions without delays. This capability enhances the quality of care in regions with limited medical infrastructure.

Data security is a critical concern in healthcare. Edge gateways address this by processing sensitive information locally, minimizing exposure to cyber threats. Features like encryption and secure boot mechanisms ensure patient data remains protected. These measures help healthcare providers comply with strict data privacy regulations.

Tip: Healthcare organizations can leverage edge computing to enhance patient care while reducing operational costs.

Smart City Initiatives

Smart cities rely on industrial edge computing gateways to manage complex urban systems efficiently. These devices process data from IoT sensors deployed across the city, enabling real-time decision-making for traffic management, energy distribution, and public safety.

In traffic management, edge gateways analyze data from road sensors and cameras to optimize traffic flow. They adjust signal timings and provide instant updates to drivers, reducing congestion and improving commute times. Similarly, in energy management, these devices monitor power grids and allocate resources based on demand, ensuring efficient energy use.

Public safety also benefits from edge computing. Smart surveillance systems use edge gateways to process video feeds locally, enabling faster detection of suspicious activities. This capability enhances response times and reduces the burden on centralized systems.

Smart waste management is another application. IoT-enabled bins equipped with edge gateways monitor fill levels and optimize collection routes. This reduces operational costs and minimizes environmental impact.

Callout: Edge gateways are the backbone of smart city initiatives, enabling efficient resource management and improved quality of life for residents.

About Robustel EG5120

Key Features of EG5120

Hardware Specifications

The Robustel EG5120 combines the functionality of a cellular router and an embedded PC, making it ideal for industrial applications. Its quad-core Cortex-A53 processor, clocked at 1.6 GHz, delivers reliable performance for real-time data processing and analytics. The device includes a Neural Processing Unit (NPU) with 2.3 TOPS, enabling accelerated machine learning inference for advanced IoT applications.

The EG5120 supports global cellular networks, including 5G, 4G, 3G, and 2G, ensuring seamless connectivity in diverse environments. It features dual Mini SIM slots for flexible network management. The gateway also offers robust connectivity options, such as dual Gigabit Ethernet ports, RS232/RS485 serial interfaces, and DI/DO inputs and outputs. These interfaces make it compatible with legacy systems and modern IoT devices.

The table below highlights the technical specifications of the EG5120:

Feature | Specification |

|---|---|

CPU | Quad core Cortex-A53, 1.6 GHz |

NPU | 2.3 TOPS |

RAM | 2 GB DDR4 |

Flash | 16 GB eMMC |

Cellular Interface | 4G/5G, 2 x Mini SIM (2FF) |

Ethernet Ports | 2 x RJ45, 10/100/1000Mbps |

Serial Interface | 2 x RS232/RS485 |

DI/DO Interface | 2 x DI + 2 x DO |

Wi-Fi Standards | 802.11 a/b/g/n/ac, 2 x 2 MIMO |

Bluetooth Standards | Bluetooth 2.1, 3.0 + EDR, 5.2 |

Operating Temperature | -40°C to 70°C |

Tip: The EG5120’s rugged design and wide operating temperature range ensure durability in harsh industrial environments.

Software Capabilities

The Robustel EG5120 runs on Debian 11 (Bullseye), a Linux-based operating system optimized for edge computing. This platform provides a stable and secure environment for running thousands of ARMv8 applications, including those compatible with Raspberry Pi. The gateway supports Docker, enabling easy deployment and management of containerized applications.

RobustOS Pro, the device’s advanced software suite, enhances cybersecurity and simplifies user interaction. It includes features like VPNs, smart roaming, and SMS remote control, ensuring secure and efficient device management. The EG5120 also supports industrial protocols such as MQTT and Modbus, facilitating seamless integration with IoT systems.

Key software features include:

Global Network Support: Compatibility with 5G/4G/3G/2G networks for reliable connectivity.

Machine Learning Acceleration: Integrated NPU for faster inference in AI applications.

Centralized Management: Robustel Cloud Manager Service (RCMS) for real-time monitoring and over-the-air updates.

Callout: The EG5120’s software capabilities empower industries to deploy scalable and secure IoT solutions with minimal effort.

Industrial edge computing gateways combine advanced hardware, robust software, and real-time data processing to revolutionize industrial operations. These devices enhance efficiency, reduce latency, and improve system reliability. Their transformative role is evident in key market trends:

The hardware segment captured over 58% of the market share in 2024, driven by demand for high-performance edge devices.

Real-time monitoring and control emerged as the largest segment, highlighting the need for immediate decision-making.

Manufacturing led the market, reflecting the growing adoption of automation in smart factories.

Callout: Businesses can unlock new possibilities by integrating edge gateways into their operations, paving the way for IoT innovation and smarter systems.

FAQ

What is an industrial edge computing gateway?

An industrial edge computing gateway is a device that processes and analyzes data locally at the edge of a network. It bridges IoT devices and cloud systems, enabling real-time decision-making and reducing latency. These gateways are essential for modern industrial and IoT applications.

How does an edge gateway improve operational efficiency?

Edge gateways process data locally, reducing the need for cloud dependency. This enables faster decision-making, minimizes downtime, and optimizes resource utilization. Industries can monitor operations in real time, identify inefficiencies, and implement corrective actions immediately, leading to improved productivity.

Are industrial edge gateways secure?

Yes, industrial edge gateways prioritize security. They include features like encryption, secure boot, and role-based access control. These measures protect sensitive data and prevent unauthorized access. Local data processing also enhances privacy by reducing exposure to external threats.

Can edge gateways work with legacy systems?

Industrial edge gateways are designed for interoperability. They support various industrial protocols, such as Modbus and MQTT, ensuring compatibility with legacy systems. This allows industries to integrate modern IoT solutions without replacing existing infrastructure.

What industries benefit most from edge computing gateways?

Industries like manufacturing, energy, transportation, healthcare, and smart cities benefit significantly. These gateways enable real-time monitoring, predictive maintenance, and efficient resource management. Their versatility makes them indispensable for diverse applications, from smart factories to remote healthcare monitoring.

Tip: Explore how edge gateways can transform your industry by enabling smarter, faster, and more secure operations.