Best Industrial Cooling Fans of 2024

Industrial cooling fans play a crucial role in various applications across North America, serving diverse industries including manufacturing, automotive, and aerospace. These fans maintain optimal operating temperatures for machinery and equipment, enhancing efficiency and longevity. The year 2024 brings significant advancements in cooling technology, focusing on innovation, efficiency, and sustainability. This blog aims to guide readers in selecting the best cooling fan for their specific needs.

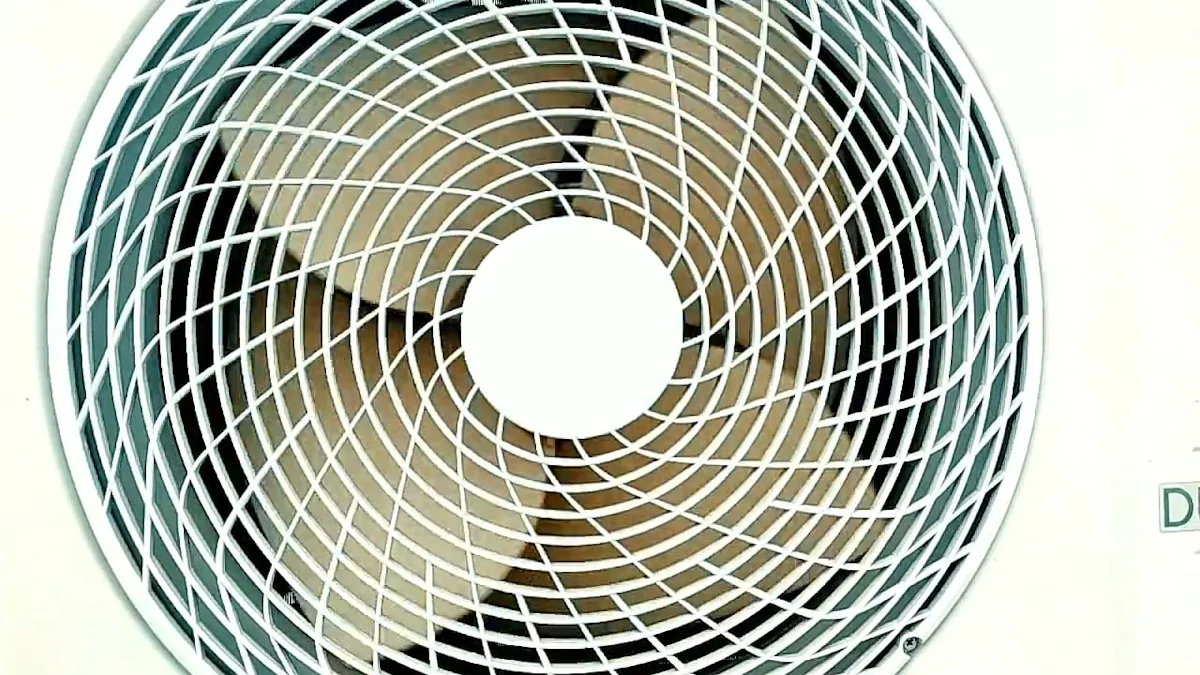

Top Industrial Cooling Fans of 2024

High-Performance Cooling Fans

X-Hon

The X-Hon cooling fan stands out for its exceptional performance. This fan delivers high airflow capacity, making it ideal for large industrial spaces. The robust construction ensures durability and long-term reliability. The X-Hon cooling fan also features advanced motor technology, which enhances efficiency and reduces operational noise. This fan remains a top choice for industries requiring powerful cooling solutions.

ycc fan

The ycc fan offers another high-performance option. This fan provides impressive airflow and efficient cooling capabilities. The design focuses on maximizing air distribution across extensive areas. The ycc fan incorporates energy-efficient motors, which help in reducing energy consumption. The sturdy build quality ensures that this fan can withstand demanding industrial environments.

Energy-Efficient Cooling Fans

ncc fan

The ncc fan excels in energy efficiency. This cooling fan utilizes advanced technology to minimize power usage while maintaining optimal performance. The ncc fan features an aerodynamic blade design, which enhances airflow and reduces energy consumption. The fan's construction includes high-quality materials, ensuring durability and longevity. Industries looking to reduce energy costs will find the ncc fan an excellent choice.

Fan D

Fan D represents another energy-efficient cooling solution. This fan combines innovative design with superior performance. The energy-efficient motor reduces electricity usage without compromising on cooling capacity. Fan D's lightweight yet durable construction makes it suitable for various industrial applications. The fan's quiet operation adds to its appeal, providing a comfortable working environment.

Budget-Friendly Cooling Fans

Fan E

Fan E offers a cost-effective cooling solution. This fan provides reliable performance at an affordable price. The simple design ensures ease of installation and maintenance. Fan E's compact size makes it ideal for smaller industrial spaces. Despite its budget-friendly nature, this fan does not compromise on essential features, delivering adequate airflow and cooling efficiency.

Fan F

Fan F stands out as another budget-friendly option. This cooling fan offers a balance between cost and performance. The fan's design focuses on providing sufficient airflow for medium-sized industrial areas. Fan F's construction uses durable materials, ensuring longevity. The straightforward design makes this fan easy to operate and maintain, making it a practical choice for budget-conscious industries.

Key Features to Consider When Choosing an Industrial Cooling Fan

Airflow Capacity

Importance of airflow capacity

Airflow capacity determines the effectiveness of a cooling fan in large industrial spaces. High airflow capacity ensures efficient temperature control and optimal working conditions. Industrial environments require fans with substantial airflow to maintain equipment and worker safety. A cooling fan with inadequate airflow may lead to overheating and reduced productivity.

How to measure airflow capacity

Measuring airflow capacity involves calculating the cubic feet per minute (CFM) that a fan can move. Higher CFM values indicate better performance in circulating air. Manufacturers often provide CFM ratings for their products. Comparing these ratings helps in selecting the most suitable cooling fan for specific industrial needs.

Energy Efficiency

Benefits of energy-efficient fans

Energy-efficient cooling fans offer significant cost savings. These fans consume less electricity, reducing operational expenses. Lower energy consumption also contributes to environmental sustainability by decreasing carbon footprints. Energy-efficient fans often feature advanced motor technologies that enhance performance without increasing power usage.

Energy ratings and certifications

Energy ratings and certifications serve as indicators of a fan's efficiency. Look for labels such as ENERGY STAR or other industry-specific certifications. These ratings ensure that the cooling fan meets stringent energy efficiency standards. Certified fans provide reliable performance while minimizing energy costs.

Durability and Build Quality

Materials used in construction

The materials used in constructing a cooling fan impact its durability and longevity. High-quality metals and plastics resist wear and tear in demanding industrial environments. Stainless steel and heavy-duty aluminum are common choices for robust fan construction. Durable materials ensure that the fan withstands harsh conditions and continuous operation.

Longevity and maintenance

Longevity and ease of maintenance are crucial factors when choosing an industrial cooling fan. Fans with durable components require less frequent replacements, reducing downtime and maintenance costs. Regular maintenance, such as cleaning and lubrication, extends the lifespan of the fan. Selecting a fan with accessible parts simplifies maintenance tasks.

Benefits of Upgrading to Modern Industrial Cooling Fans

Improved Efficiency

Energy savings

Modern industrial cooling fans incorporate advanced motor technology. These motors consume less electricity. Lower energy consumption translates to significant cost savings. Efficient cooling fans reduce the overall carbon footprint of industrial operations.

Enhanced performance

Enhanced performance characterizes modern cooling fans. Advanced designs optimize airflow. Improved airflow ensures better temperature regulation. Consistent temperature control enhances productivity in industrial environments.

Cost Savings

Lower operational costs

Modern cooling fans lower operational costs. Energy-efficient motors reduce electricity bills. Durable materials minimize the need for frequent replacements. Reduced downtime contributes to overall cost efficiency.

Reduced maintenance expenses

Modern cooling fans require less maintenance. High-quality components ensure longevity. Fewer breakdowns result in lower maintenance expenses. Regular upkeep becomes simpler with accessible parts.

Enhanced Workplace Safety

Better temperature control

Better temperature control improves workplace safety. Modern cooling fans maintain consistent temperatures. Controlled environments prevent equipment overheating. Stable temperatures enhance worker comfort and safety.

Reduced risk of overheating

Reduced risk of overheating protects machinery. Modern cooling fans provide efficient heat dissipation. Proper cooling prevents equipment failures. Reliable cooling solutions ensure uninterrupted operations.

The top industrial cooling fans of 2024 include high-performance options like the X-Hon and ycc fan, energy-efficient models such as the ncc fan and Fan D, and budget-friendly choices like Fan E and Fan F. Making an informed decision requires evaluating airflow capacity, energy efficiency, and durability. Key features and benefits should guide the selection process. Explore the recommended products to find the ideal cooling solution for specific industrial needs. Consider making a purchase to enhance operational efficiency and workplace safety.

See Also

Best Power Banks to Consider for 2024

Essential AGV Tech Updates to Stay Informed

Key Strategies for Personalizing Your Jewelry Display