AMR vs AGV - Key Differences Explained

AMRs and AGVs differ in several critical ways. AMRs navigate autonomously, make decentralized decisions, and adapt to dynamic environments. AGVs follow fixed guide paths and rely on centralized control. Production networks using AMRs show 1.7 to 2 times greater flexibility than those with traditional AGVs, highlighting key differences in adaptability and intelligence.

Aspect | AMR Features | AGV Features |

|---|---|---|

Navigation | Autonomous, dynamic routing | Fixed paths, central control |

Flexibility | Agile, operates without external guidance devices | Bulky, needs frequent human intervention |

Intelligence | AI-driven, optimized routing | Limited, relies on fixed paths |

Key Takeaways

AMRs navigate independently using AI and sensors, while AGVs follow fixed paths and need manual updates.

AMRs adapt quickly to changes and obstacles, improving safety and efficiency in dynamic environments.

AGVs work well in stable settings with repetitive tasks but lack flexibility and require more infrastructure.

AMRs offer faster setup, easier scaling, and better integration with modern warehouse systems.

Choosing between AMRs and AGVs depends on your facility’s layout, workflow needs, and future growth plans.

Definitions

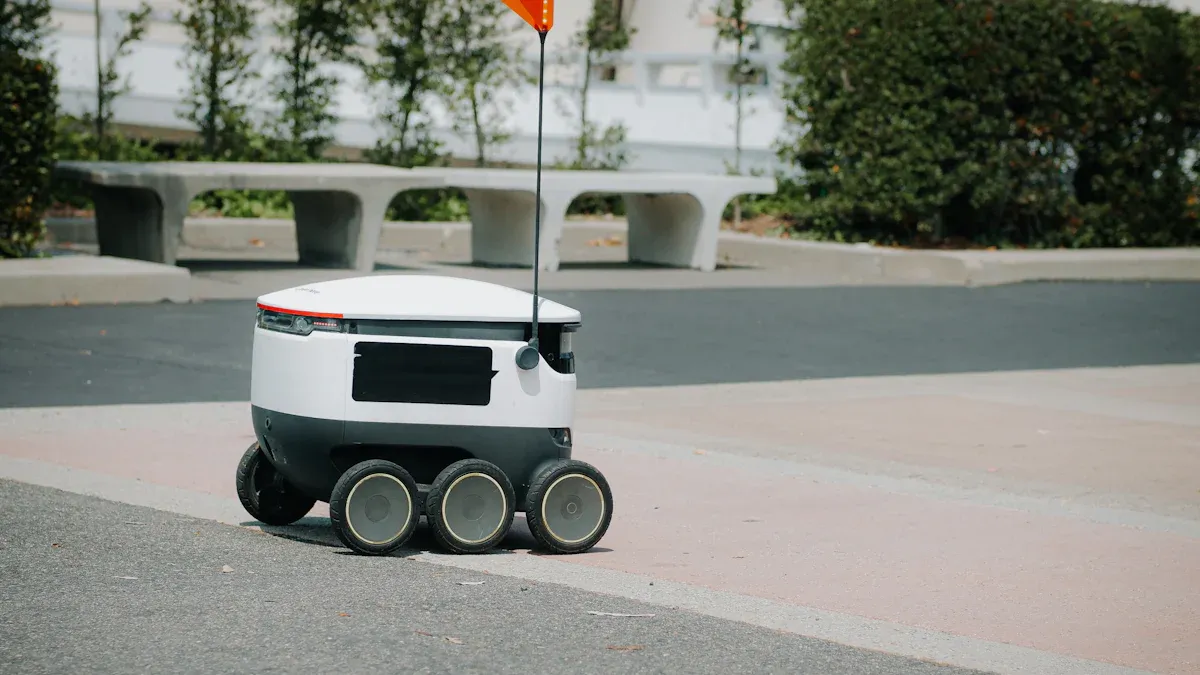

Autonomous Mobile Robots

Autonomous mobile robots, often called AMRs, represent a new generation of intelligent machines designed for dynamic environments. These robots use advanced sensors, artificial intelligence, and navigation technologies such as lidar to move freely and safely. AMRs do not rely on fixed paths or external guidance systems. Instead, they analyze their surroundings in real time and make decisions independently. This flexibility allows them to adapt to changes in the environment, such as obstacles or shifting layouts.

AMRs often integrate with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. This integration enables real-time inventory tracking and improves operational accuracy. The Innorobix article highlights how AMRs excel in complex settings, offering greater flexibility and efficiency than traditional automated guided vehicles.

The Robot Report's Autonomous Mobile Robotics Week emphasizes that AMRs come in various types and serve many industries. Experts discuss safety standards, interoperability, and practical use cases, showing how these robots transform warehouse and manufacturing operations. Companies deploy AMRs to boost productivity, reduce errors, and handle repetitive tasks, freeing human workers for higher-value activities.

Automated Guided Vehicles

Automated guided vehicles, or AGVs, are mobile robots that follow fixed routes within a facility. These robots use physical guides such as magnetic strips, wires, or tracks embedded in the floor. AGVs rely on centralized control systems to direct their movements. Unlike AMRs, AGVs cannot change their path without manual intervention or reprogramming.

AGVs have served warehouses and factories for decades. They transport goods along predetermined paths, making them suitable for stable, predictable environments. Many organizations choose AGVs for simple, repetitive material handling tasks. However, AGVs lack the flexibility and intelligence found in autonomous mobile robots.

AGVs offer reliable performance in controlled settings.

They require less complex software but need more human oversight for changes.

AGVs remain a popular choice for facilities with minimal layout changes.

Key Differences

Navigation

Navigation stands as one of the key differences between autonomous mobile robots and traditional agvs. AGVs rely on fixed paths, such as magnetic strips or reflective markers, which limits their navigation capabilities. These automated guided vehicles follow predetermined routes and require manual intervention for any changes. This approach restricts their autonomy and adaptability.

In contrast, AMRs use advanced navigation systems that combine cameras, AI, and sensor fusion. These robots recognize their surroundings and adjust routes dynamically. Vision guidance and hybrid navigation allow AMRs to create real-time maps and reroute as needed. This level of autonomy enables AMRs to operate efficiently in environments with frequent layout changes, such as warehouses and distribution centers. Their navigation capabilities support higher efficiency and reliability, especially when compared to traditional agvs.

AMRs demonstrate superior performance in dynamic settings, adapting to new layouts without the need for physical infrastructure changes.

Obstacle Handling

Obstacle handling highlights another major difference between AMRs and traditional agvs. AGVs stop when they encounter obstacles on their fixed paths. They often require human assistance to resume operation, which disrupts workflow and reduces efficiency. Traditional agvs lack real-time obstacle avoidance and cannot reroute around unexpected barriers.

AMRs excel in real-time obstacle avoidance. These robots use LiDAR, computer vision, and SLAM algorithms to detect and navigate around obstacles. They maintain safety zones and adjust their paths instantly, ensuring continuous operation. Research shows that AMRs engage obstacle avoidance during 80% of their trips, demonstrating their dynamic navigation and planning abilities. This capability leads to improved performance and reliability in busy environments.

AMRs handle complex tasks, such as pallet pick-up, with greater flexibility.

They tolerate slight inaccuracies in placement, which would hinder traditional agvs.

Real-time route planning and path planning allow AMRs to maintain operational flow.

Flexibility

Flexibility sets AMRs apart from traditional agvs in material handling operations. AGVs depend on fixed routes and physical infrastructure, making them less adaptable to changes. Any modification in workflow or layout requires manual resets and route recommissioning. This process limits the scalability and efficiency of traditional agvs.

AMRs leverage advanced sensors, AI, and real-time path planning to adapt to obstacles, payload variations, and changing workflows. These robots operate efficiently in narrow or crowded spaces and scale easily with operational needs. Their autonomy supports faster deployment and return on investment, as they require minimal infrastructure. AMRs' flexibility ensures reliable performance even as business demands evolve.

Companies seeking scalable automation benefit from the flexibility and autonomy of AMRs, especially in dynamic environments where traditional agvs struggle.

Safety

Safety features play a crucial role in the adoption of robots in shared workspaces. Both AMRs and AGVs reduce manual handling risks, but AMRs offer enhanced safety in environments where humans and robots interact. AMRs use advanced sensors, 3D depth cameras, and LiDAR technology to detect both stationary and moving obstacles. These robots dynamically replan routes to avoid collisions, ensuring safe operation.

Traditional agvs follow fixed paths and stop when an obstacle appears, lacking the ability to reroute. This limitation can cause operational stoppages and indirectly affect safety. AMRs, on the other hand, use machine learning and cloud-based intelligence to adapt their movement behavior. Their safety features enable them to operate reliably around people, forklifts, and other equipment.

AMRs provide superior safety in mixed human-robot environments.

Their real-time obstacle avoidance and planning capabilities reduce the risk of accidents.

Reliability and efficiency improve as AMRs adapt to changing conditions.

The fundamental difference in navigation and obstacle avoidance technology supports the claim that AMRs deliver better safety and reliability in dynamic workplaces.

Deployment

Setup

Setting up AMRs and AGVs involves careful planning and attention to detail. Companies must first assess their operational challenges, transport flows, and integration points. Pre-project planning often includes collecting baseline data and defining key performance indicators (KPIs). Technical specifications play a crucial role. Teams evaluate navigation technologies—such as magnetic guidance, laser, or SLAM—and select fleet management software that fits their needs.

Facility layout design and multi-robot coordination are essential for automated warehousing, as highlighted by recent studies in logistics and manufacturing. For example, large-scale AMR deployments in automotive manufacturing require zone design, conflict-free routing, and dynamic dispatching strategies to ensure smooth operations.

Common setup steps include:

Reviewing site conditions and preparing the facility for robot movement.

Designing loading and unloading points to optimize material flow.

Ensuring system compatibility with existing infrastructure.

Conducting acceptance testing to verify performance and safety.

Companies often face challenges like poor scope definition or inadequate site preparation. Successful projects emphasize long-term planning, stakeholder involvement, and comprehensive training. Teams that focus on scalability, reliability, and compliance with safety standards achieve better results.

Integration

Integrating AMRs and AGVs into existing systems requires a structured approach. Teams start by defining detailed requirements, including payload, speed, battery life, and software integration needs. Vendor evaluation follows, with a focus on support and system stability. Pilot testing helps identify potential issues before full-scale deployment.

A typical integration process includes:

Mapping warehouse layouts and defining communication protocols.

Starting with a small application area to build expertise.

Measuring performance and return on investment with clear metrics.

Expanding implementation in phases and optimizing workflows.

Involving frontline workers early and providing comprehensive training.

Successful integration stories, such as Alibaba’s warehouse automation, show that combining AMRs with automated storage and retrieval systems can triple output and reduce workforce needs by 70%. AMRs’ advanced navigation and adaptability allow seamless integration without major infrastructure changes. These robots work alongside human operators, improving productivity and morale while ensuring safety and scalability.

Cost

Initial Investment

When evaluating automation solutions, companies must consider the initial investment required for AMRs and AGVs. The cost structure for each technology differs significantly. AMRs typically demand a higher upfront investment in hardware and software, while AGVs require more spending on infrastructure modifications. The following table summarizes the typical cost breakdown:

Cost Component | AMRs (% of total cost) | AGVs (% of total cost) |

|---|---|---|

Hardware | 60-70% | 30-40% |

Software | 25-30% | 10-15% |

Infrastructure | 5-10% | 45-60% |

AMRs often cost between $25,000 and $100,000 per unit. Their advanced navigation and intelligence drive up hardware and software expenses. However, they require minimal changes to existing facilities, which helps avoid costly disruptions. AGVs, on the other hand, range from $10,000 to $50,000 per unit but may need infrastructure investments that can exceed $120,000. These modifications include installing magnetic strips or tracks and can lead to facility downtime.

Companies deploying AMRs benefit from faster implementation, often completing projects in two to four weeks. AGV deployments may take two to three months, affecting cash flow and productivity.

Flexible financing options, such as Robots-as-a-Service (RaaS), have become more common for AMRs. This model reduces upfront capital requirements and allows businesses to scale automation as needed.

Maintenance

Long-term financial planning must account for maintenance costs. AGVs have demonstrated significant operational savings by reducing manual labor. For example, one company replaced three employees with AGVs, saving over EUR 79,000 annually and recovering its investment in about eight months. Over time, the company saved EUR 756,000 in wage costs for 18 operators.

AMRs use predictive maintenance powered by sensor data and analytics. This approach helps anticipate failures before they occur, reducing unplanned downtime and extending robot lifespan. Remote diagnostics enable centralized monitoring and faster troubleshooting, which minimizes service delays. Effective spare parts management ensures quick component replacement, preventing prolonged interruptions.

Both AMRs and AGVs offer long-term financial benefits. AGVs provide savings through labor reduction and continuous operation. AMRs deliver additional value by maximizing uptime and operational efficiency through advanced maintenance strategies. These factors make both technologies attractive for organizations seeking to optimize costs and improve productivity.

Applications

AMR Use Cases

Autonomous mobile robots have transformed warehouse operations and industrial applications by delivering flexibility and intelligence. Companies deploy AMRs to transport materials, manage inventory, and optimize workflows. These robots adapt to changing layouts and obstacles, making them ideal for dynamic environments.

ForwardX Robotics' Omni Fleet stands out in the AMR market. This suite of robots integrates deep learning and advanced sensors to boost warehouse efficiency. In one deployment, a 3PL provider reported a 113% increase in units picked per hour and a 52% reduction in operational costs. Retail and e-commerce companies have seen error rates drop from 1 in 10,000 to 1 in 100,000 after implementing Omni Fleet with RFID technology.

Exotec’s Skypod system demonstrates AMR success across e-commerce, grocery, and automotive supply chains. These robots work alongside humans, handling complex sorting and picking tasks.

In the public sector, hospitals and libraries use AMRs to automate repetitive transport tasks, freeing staff for higher-value work.

AMRs excel in applications where flexibility, safety, and rapid adaptation are critical. Their ability to integrate with warehouse management systems further enhances operational efficiency.

AGV Use Cases

AGVs remain valuable in industrial applications that require repetitive, predictable movement. These robots transport materials along fixed routes in large warehouses and manufacturing plants. Automotive factories often use AGVs to move heavy parts between assembly lines. In general manufacturing, AGVs support just-in-time delivery by following established paths.

AGVs suit applications with stable layouts and minimal need for route changes. Companies choose AGVs for their reliability in environments where tasks rarely change. While traditional agvs lack the flexibility of AMRs, they continue to play a role in supporting warehouse operations that prioritize consistency.

AGVs provide dependable solutions for facilities focused on routine transport and structured workflows.

Decision Guide

Choosing AMR

Organizations operating in dynamic environments often benefit most from autonomous mobile robots. AMRs excel in facilities where layouts change frequently, workflows evolve, or multiple tasks require coordination. Data-driven decision making supports the use of AMRs by allowing manufacturers to analyze real-time sensor data and operational metrics. This approach enables teams to adapt quickly to new demands and optimize robot deployment.

A comparison of AGVs and AMRs highlights key differences:

Aspect | AGVs | AMRs |

|---|---|---|

Navigation | Fixed routes, minimal intelligence | Intelligent, autonomous rerouting |

Route Flexibility | Limited, costly to modify | High, software-based changes |

Safety | Basic sensors, manual intervention | Advanced AI, dynamic obstacle avoidance |

Cost and Installation | High infrastructure costs, disruptive | Lower infrastructure costs, rapid deployment |

Operational Environment | Best for static, stable settings | Ideal for agile, changing environments |

Task Flexibility | Repetitive, fixed tasks | Multiple tasks, managed by fleet control software |

ForwardX Robotics’ Omni Fleet demonstrates the advantages of advanced AMRs in real-world settings. At Chery Automotive’s Super Factory, Omni Fleet increased efficiency by 200% and reduced logistics costs by 10%. The system maintained low error rates and improved inventory management, showing the value of flexibility and scalability in complex operations. Companies facing labor shortages or seeking to modernize their warehouses often choose AMRs for their adaptability and rapid return on investment.

Tip: Select AMRs when your facility requires frequent layout changes, diverse workflows, or integration with advanced software systems.

Choosing AGV

AGVs remain a strong choice for organizations with stable, predictable operations. These vehicles perform best in environments where routes rarely change and tasks remain consistent. AGVs follow fixed paths, making them suitable for traditional manufacturing lines or warehouses with minimal variation.

Facilities that prioritize reliability and have already invested in infrastructure for AGVs may continue to see value in these systems. AGVs offer dependable performance for repetitive transport tasks and can reduce manual labor in controlled settings.

Note: Choose AGVs when your operation values consistency, has a fixed layout, and does not require frequent changes to routes or workflows.

For businesses seeking future-proof automation, advanced AMR solutions like ForwardX Robotics’ Omni Fleet provide unmatched flexibility and scalability. These systems adapt to evolving business needs and support growth without major infrastructure changes.

Decision-makers should compare both solutions using clear criteria:

Criteria | AMR | AGV |

|---|---|---|

Navigation | Autonomous, flexible | Fixed, predictable |

Safety | Avoids obstacles | Stops at obstacles |

Installation | Fast, no construction | Needs construction |

Flexibility | Scalable, software-based | Hard to change |

Reliability | Adapts to change | Consistent, plannable |

Investment | Higher upfront, less retrofit | Lower upfront, more infrastructure |

AGVs work best for stable, predictable routes. AMRs suit dynamic environments needing flexibility and quick setup. Companies should assess operational needs, budget, and future growth before choosing a solution.

FAQ

What is the main difference between an AMR and an AGV?

AMRs navigate using sensors and AI, making real-time decisions. AGVs follow fixed paths set by physical guides. AMRs adapt to changes in the environment, while AGVs require manual updates for any route changes.

Can AMRs and AGVs work together in the same facility?

Yes, many facilities deploy both AMRs and AGVs. AMRs handle dynamic tasks and adapt to changes. AGVs manage repetitive, fixed routes. This combination increases efficiency and supports a wider range of workflows.

How does ForwardX Robotics’ Omni Fleet improve warehouse operations?

Omni Fleet uses advanced AMRs with deep learning. These robots increase picking speed, reduce errors, and lower operational costs. Companies report up to 113% more units picked per hour and a 52% drop in costs after deploying Omni Fleet.

Are AMRs safe to use around people?

AMRs use sensors, cameras, and AI to detect people and obstacles. They adjust their paths instantly to avoid collisions. This technology ensures safe operation in busy environments, even when humans and robots share the same workspace.

What industries benefit most from AMRs?

Industries such as 3PL, retail, e-commerce, automotive, and the public sector see the greatest benefits. AMRs support flexible workflows, rapid scaling, and high accuracy, making them ideal for environments with changing demands and layouts.